Brother International BAS-326E Network Users Manual - English - Page 60

Adjusting the needle clearance, 4. Adjusting the driver needle guard, 5. Adjusting the shuttle

|

View all Brother International BAS-326E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 60 highlights

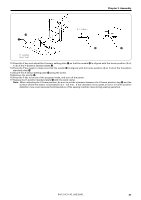

Chapter 4. Adjustments 3. Adjusting the needle clearance q 0.01 - 0.08mm w Turn the machine pulley to align the tip of the rotary hook with the needle center line. Then loosen the set screw q and turn the eccentric shaft w to adjust so that the clearance between the needle and the rotary hook is 0.01 - 0.08 mm. 4. Adjusting the driver needle guard q w e Turn the machine pulley to align the tip of the rotary hook with the needle center line. Then loosen the set screw w and turn the eccentric shaft e to adjust so that the driver needle guard q contacts the needle. If the needle contact pressure is too great, skipped stitches may occur. On the other hand, if the driver needle guard q is not touching the needle, the tip of the inner rotary hook will obstruct the needle, resulting in an excessively high amount of friction. 5. Adjusting the shuttle race thread guide q A Install the shuttle race thread guide q by pushing it in the direction of the arrow so that the needle groove is aligned with the center of the needle plate hole. Note:If the shuttle race thread guide is in the wrong position, thread breakages, soiled thread or catching of the thread may occur. 52 BAS-311E.311EL.326E.326EL