Hayward CAT 3500 CAT 3500 Owners Manual - Page 7

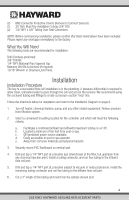

Typical CAT 3500 Installation Diagram

|

View all Hayward CAT 3500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

Typical CAT 3500 Installation Diagram 6 USE ONLY HAYWARD GENUINE REPLACEMENT PARTS pH ORP Cond. CAT PRO15 CAT PRO25 CAT PRO55 pH Sensor ORP Sensor COND. Sensor Flow pH ORP Cond. CAT Controllers CAT 3500TM WATER QUALITY CONTROLLER pH Cl/Br FEED FEED ALARM MENU UP DOWN ENTER TRANSMIT POOLCOMM ENABLED CAT 3500 SYSTEM Flow Switch Sample Stream Influent (to Return Line) Effluent (to Suction) Power Cord ORP Feed Output pH Feed Output Chemical Pump or CAT CO2 pH Control Solenoid Flow Cell / Flow Sensor Bypass Line Flow Flow Flow WASTE Chemical Pump or Erosion Feeder Solenoid Main Drain and Skimmer SUCTION LINE Flow PUMP FILTER RETURN LINE Flow Pressure Differential

USE ONLY HAYWARD GENUINE REPLACEMENT PARTS

6

Typical CAT 3500 Installation Diagram

WATER QUALITY CONTROLLER

MENU

UP

DOWN

ENTER

TRANSMIT

CAT 3500

TM

POOLCOMM

ENABLED

pH

Cl/Br

FEED

FEED

ALARM

Flow

Main Drain

and Skimmer

Flow

Flow

Flow

Flow Cell / Flow Sensor Bypass Line

Solenoid

Flow

Pressure

Differential

Solenoid

CAT CO2

pH Control

Erosion

Feeder

or

or

Chemical

Pump

Chemical

Pump

pH Feed Output

Power Cord

ORP Feed Output

Sample

Stream

Influent

(to Return Line)

Effluent

(to Suction)

CAT 3500

SYSTEM

CAT Controllers

SUCTION LINE

PUMP

FILTER

WASTE

RETURN LINE

pH

ORP

Cond.

Flow

Switch

Flow

Cond.

pH

ORP

CAT PRO15

pH

Sensor

CAT PRO25

ORP

Sensor

CAT PRO55

COND.

Sensor