Intel E6420 Design Guidelines - Page 112

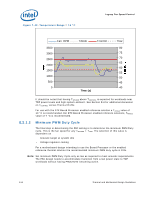

E.2.1.1, Temperature to begin fan acceleration

|

UPC - 735858192569

View all Intel E6420 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 112 highlights

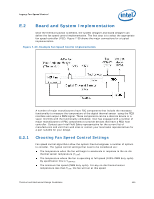

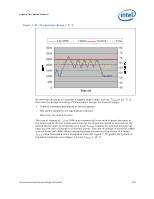

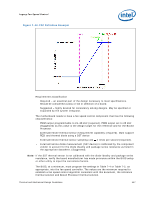

Legacy Fan Speed Control These are the minimum parameters required to implement acoustic fan speed control. See Figure 7-40 for an example. There may be vendor specific options that offer enhanced functionality. See the appropriate vendor datasheet on how to implement those features. Figure 7-40. Fan Speed Control Full Speed 100 % Min Speed X % TLOW TCONTROL Diode Temperature (°C) E.2.1.1 Temperature to begin fan acceleration The first item to consider is the value for TLOW. The FSC device needs a minimum temperature to set as the threshold to begin increasing PWM duty cycle to the fan. The system designer might initially consider a small temperature range (TCONTROL - TLOW = TRANGE), 5 °C to accelerate the fan. That would delay the fan accelerating for the longest time after an increase in TSENSOR. There are a number of issues that should be considered with this strategy There is little granularity in the fan speeds. For each 1 °C of increase in diode temperature = 20% jump in PWM duty cycle % Fan speed oscillation as the thermal solution chases the on-die thermal sensor temperature Having TSENSOR overshoot TCONTROL and the thermal profile causing the Thermal Control Circuit to activate to reduce the temperature. In extreme cases THERMTRIP# activates and shuts down the processor The first two cases can create a poor acoustic response for the user. The third case the user could notice a drop in performance as the thermal control circuit reduces the power. Figure 7-41 is an example of this situation. The system begins at idle and the Maxpower program is started at 65% workload. 112 Thermal and Mechanical Design Guidelines