LiftMaster GH GH LOGIC VERSION 2 Manual - Page 3

Specifications - 1 2 hp

|

View all LiftMaster GH manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

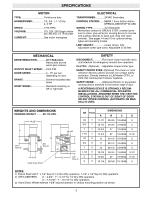

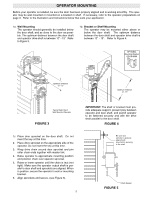

SPECIFICATIONS MOTOR TYPE Continuous duty HORSEPOWER 1/2, 3/4, 1, 1-1/2 Hp 2, 3 HP SPEED 1725 RPM VOLTAGE 115, 220, 230 Single phase 230, 380, 460, 575 Three phase CURRENT See motor nameplate ELECTRICAL TRANSFORMER 24VAC Secondary CONTROL STATION: ......NEMA 1 three button station OPEN/CLOSE/STOP W/ LED WIRING TYPE C2 (Standard) Momentary contact to OPEN & STOP, constant pressure to close, plus wiring for sensing device to reverse and auxiliary devices to open and close with open override. See pages 14 and 15 for optional wiring types and operating modes. LIMIT ADJUST Linear driven, fully adjustable screw type cams. Adjustable to 30 feet. MECHANICAL DRIVE REDUCTION 40:1 Reduction Heavy duty bronze worm gear reducer OUTPUT SHAFT SPEED:.....43 R.P.M. DOOR SPEED 4 - 10" per sec. depending on door BRAKE Solenoid actuated disc brake HOIST WHEEL Standard mounting on left or right side SAFETY DISCONNECT Floor level chain hoist with electrical interlock for emergency manual door operation CLUTCH: (Optional) ....Adjustable torque limiter type SAFETY PHOTO EYES: (Optional) Thru beam or retro reflective devices used to provide non-contact safety protection. Directly interface to Lift Master CPS-L or CPS-LN4 Commercial Protector Systems. SAFETY EDGE Optional) Electric or pneumatic sensing device attached to the bottom edge of door. A REVERSING DEVICE IS STRONGLY RECOMMENDED FOR ALL COMMERCIAL OPERATOR INSTALLATIONS. REQUIRED WHEN THE 3 BUTTON CONTROL STATION IS OUT OF SIGHT OF DOOR OR ANY OTHER CONTROL (AUTOMATIC OR MANUAL) IS USED. WEIGHTS AND DIMENSIONS HANGING WEIGHT: .........80-110 LBS. 14.00" A Y See Note #2 B See Note #1 X C Hand Chain Wheel D Y See Note #3 HP PHASE A 1/2 1 11-1/2 3/4 1 12-1/2 1 1 12-3/4 1-1/2 1 12-3/4 1/2 3 11 3/4 3 11 1 3 12 1-1/2 3 12-1/2 2 3 12-3/4 3 3 13-1/4 DIMENSIONS B C D 25-3/4 12-63/64 3 26-3/4 12-63/64 3 27 12-63/64 3 27 13-63/64 3-1/2 25-1/4 12-63/64 3 25-1/4 12-63/64 3 26-1/4 12-63/64 3 26-3/4 13-63/64 3-1/2 27 13-63/64 3-1/2 28-5/8 15-15/64 3 NOTES: 1) Output Shaft with 1" x 1/4" Key for 1/2 thru 2Hp operators, 1-1/4" x 1/4" Key for 3Hp operators. 2) MT'G CENTERS: X = 4-3/4"; Y = 5-1/2" for 1/2 thru 2Hp operators X = 7-17/32"; Y = 9-1/16" for 3Hp operators 3) Hand Chain Wheel extends 1-5/8" beyond operator in vertical mounting position as shown. 3