LiftMaster GH GH LOGIC VERSION 2 Manual - Page 4

Warning - door spring adjustment

|

View all LiftMaster GH manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 4 highlights

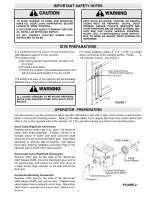

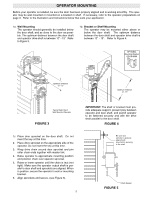

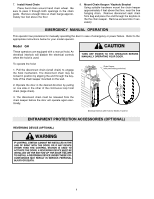

IMPORTANT SAFETY NOTES CAUTION WARWNAINRGNING W TO AVOID DAMAGE TO DOOR AND OPERATOR, MAKE ALL DOOR LOCKS INOPERATIVE. SECURE LOCK(S) IN "OPEN" POSITION. IF THE DOOR LOCK NEEDS TO REMAIN FUNCTIONAL, INSTALL AN INTERLOCK SWITCH. DO NOT CONNECT ELECTRIC POWER UNTIL INSTRUCTED TO DO SO. KEEP DOOR BALANCED. STICKING OR BINDING DOORS MUST BE REPAIRED. DOORS, DOOR SPRINGS, CABLES, PULLEYS, BRACKETS AND THEIR HARDWARE MAY BE UNDER EXTREME TEN- SION AND CAN CAUSE SERIOUS PERSONAL INJURY. CALL A PROFESSIONAL DOOR SERVICE- MAN TO MOVE OR ADJUST DOOR SPRINGS OR HARDWARE. CAUTION SITE PREPARATIONS It is imperative that the wall or mounting surface provide adequate support for the operator. This surface must: a) Be rigid to prevent play between operator and door shaft. b) Provide a level base. c) Permit the operator to be fastened securely and with the drive shaft parallel to the door shaft. The safety and wear of the operator will be adversely affected if any of the above requirements are not met. For metal buildings, fasten 2" x 2" x 3/16" (or larger) angle iron frames to the building purlins. Retain 51/2" between frames. See Figure 1. Shaft Support Bracket with Bearing (Not Supplied) Door Sprocket WARNING WARNING ALL DOORS INTENDED TO BE MOTOR OPERATED SHOULD BE MANUFACTURED WITH SOLID DOOR SHAFTS. 25-1/24"" FIGURE 1 OPERATOR PREPARATION CAUTION WARNING The GH operator may be mounted on either the right (standard) or left side of door, and in either a vertical (stan- dard) or horizontal mounting position. Refer to the steps below if you require the hand chain and/or disconnect chain to be on the opposite side of the operator; Or if the operator is being mounted in a horizontal position. Hand Chain Right/Left Conversion Remove the two snap rings (1 pc. outer, 1 pc inner) on hand chain shaft assembly. Position roll-pin to fit through cutout in frame and slide complete shaft assembly through housing and bevel gear. Insert shaft assembly on opposite side of housing, and replace bevel gear, bearing, hardware, and snap rings on the opposite side of shaft in the same manner. Disconnect Lever Right/Left Conversion Remove cotter pins on the ends of the disconnect shaft (square shaft), move the disconnect lever arm to the opposite side, and replace the cotter pins. Be sure to keep two(2) 12ga. washers on the side without the lever arm. Horizontal Mounting Conversion Remove cotter pins on the ends of the disconnect shaft (square shaft), and remove lever. Replace lever using square hole on opposite end of lever. Reposition sash chain to opposite end of lever also. Replace cot- ter pins. 4 Chain Guide CAUTION LOCISNAISTTTEEFAMOCOLUFOLRSNPMITNETOBRRDREOSOEOLOCTNORSHTNOUCAATPNSTROEEI8OOSROFLNNAWNTLTSE.LNINOAYDIBGETTBOHTYCCVHA3ETEHTBDDCUOOORT-OIONTNRSOERTRNSIEVSOSTLWEET.AIRDTRTIOHINUOOSINNRSCINTTGAIOLENLDASGTIEON Hand Chain Wheel Cutout for Rollpin (typical both sides) Disconnect Lever Cotterpin FIGURE 2