Panasonic SAHT730 Technical Guide - Page 7

Simulated Failure Symptoms - quick fixes - sa ht730 back panel

|

View all Panasonic SAHT730 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

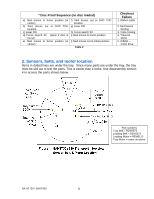

3. Simulated Failure Symptoms - quick fixes Although sensor failures cause the following symptoms listed in table 3, the more common failure is an internally broken ribbon cable that carries the sensor signal to the microprocessor. To determine which is at fault, begin testing using figures 4 and 5 or order the cable with the corresponding sensor. For example the motors (#6 & #7 in table 3) and S9001 (#4) can be quickly checked with an ohmmeter at the CN2010/2011 cable end (see figures 4 or 5). If the part tests bad bypass the cable and recheck the part right at the part's terminal. CN2010 ribbon cable p/n = REZ1484 (11 pins) CN2011 ribbon cable p/n = REZ1483 (10 pins) Sensor 1. Disc Det Q9103 open 2. Tray rotation Q9102 open. 3. Tray position Q9101 open. 4. Main gear position Q9001 open. 5. Tray out switch S9001 open. 6. Tray Loading Motor 7. Tray Rotation Motor Cable CN2010 CN2010 CN2010 CN2011 CN2011 CN2011 CN2010 Simulated Failures Symptom No disc detected (no PB possible). Tray motor rotates back & forth for ¼ rotation then shuts down. H01 error code shown. Slow continuous CCW rotation of the tray. "INIT" appears and no buttons work except power. Tray moves out and spins, then the tray moves in. and the mech clamps & then unclamps. Repeats. Normal start up. Pressing the open tray button permits the tray to open but it closes automatically. Front panel display = "Please Wait" or "Open/Close" Front panel display = "Please Wait" Table 3 Comments Unit shuts down. Unit does not shutdown. Unit does not shutdown. Tray will not stay open. Motor = 14 ohms SA-HT730 / SAHT930 7