Pfaff hobbylock 756 Owner's Manual - Page 42

Cleaning, Machine, Oiling, Maintenance

|

View all Pfaff hobbylock 756 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 42 highlights

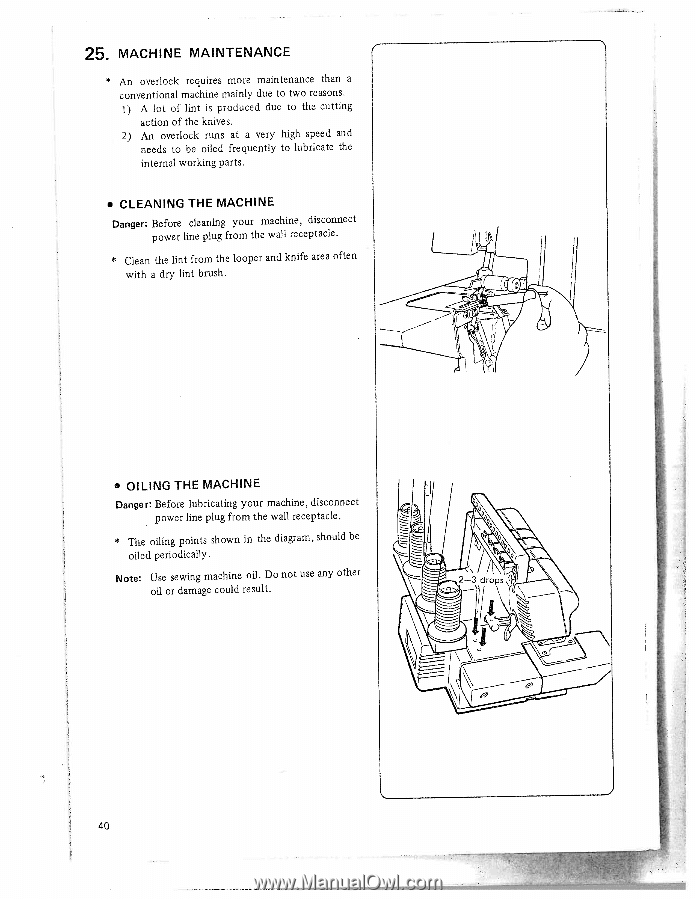

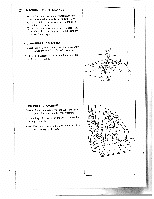

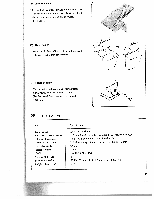

25. MACHINE MAINTENANCE * An overlock requires more maintenance than a conventional machine mainly due to two reasons. 1) A lot of lint is produced due to the cutting action of the knives. 2) An overlock runs at a very high speed and needs to be oiled frequently to lubricate the internal working parts. . CLEANING THE MACHINE Danger: Before cleaning your machine, disconnect power line plug from the wall receptacle. * Clean the lint from the looper and knife area often with a dry lint brush. • OILING THE MACHINE Danger: Before lubricating your machine, disconnect power line plug from the wall receptacle. * The oiling points shown in the diagram, should be oiled periodically. Note: Use sewing machine oil. Do not use any other oil or damage could result. 40 /