Ariens Compact Track 24 Owners Manual - Page 21

Pre-start, To Stop In An Emergency, Starting And Shut Off, Check Axle Lock Pins

|

View all Ariens Compact Track 24 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

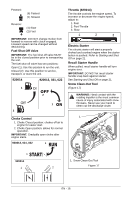

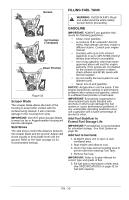

IMPORTANT: DO NOT OVERFILL! This equipment and/or its engine may include evaporative emissions control system components, required to meet EPA and/or CARB regulations, that will only function properly when the fuel tank has been filled to the recommended level. Overfilling may cause permanent damage to evaporative emissions control system components. Filling to the recommended level ensures a vapor gap required to allow for fuel expansion. Pay close attention while filling the fuel tank to ensure that the recommended fuel level inside the tank is not exceeded. Use a portable gasoline container with an appropriately sized dispensing spout when filling the tank. Do not use a funnel or other device that obstructs the view of the tank filling process. 6. Replace fuel cap and tighten. 7. ALWAYS clean up spilled fuel. PRE-START 1. Frozen Impeller IMPORTANT: Before starting engine, check impeller to be sure it is not frozen. To check impeller: 1. With ignition key switch in "Stop" position, squeeze Attachment Clutch Lever to Engaged position. 2. Pull Recoil Starter Handle. 3. If Impeller is frozen, (cannot pull Recoil Starter Handle) move unit to a heated area and thaw to prevent possible damage. 2. Check Function of Clutches If clutches do not engage or disengage properly, adjust or repair before operation. See Attachment Clutch/Brake Adjustment on page 30 and Traction Drive Clutch Adjustment on page 33. 3. Check Dual Handle Interlock Without the engine running, press down (engage) both clutch levers. Release attachment clutch lever. Attachment clutch should remain engaged until traction drive clutch lever is released, then both clutches must disengage. If clutches do not engage or disengage properly, adjust or repair before operation. See Attachment Clutch/Brake Adjustment on page 30 and Traction Drive Clutch Adjustment on page 33. 4. Check Axle Lock Pins (920013, 014, 021) Use the axle lock pins to lock or unlock the wheels. Lock both wheels to increase traction; unlock one wheel to allow for easier turning of the unit. 5. Check Skid Shoes Check and adjust skid shoes (see Skid Shoes on page 28). Allow 1/8" (3 mm) between scraper blade and hard, smooth surface(s). Allow 7/8" (22 mm) between scraper blade and uneven or gravel surfaces. 6. Check Engine Fuel & Crankcase Oil WARNING: AVOID INJURY. Read and understand the entire Safety section before proceeding. Check and add fuel if required. Check that the engine crankcase oil is full using dipstick. Refer to Engine Manual for detailed instructions. TO STOP IN AN EMERGENCY Immediately release both clutch levers to stop unit in an emergency. Stop engine, remove key and wait for all rotating parts to stop before leaving operator's position. STARTING AND SHUT OFF WARNING: FAILURE TO FOLLOW INSTRUCTIONS could result in personal injury and/or damage to unit. DO NOT attempt to start your unit at this time. Read entire Owner/Operator Manual and the Engine Manual first. IMPORTANT: Allow unit and engine to adjust to the outdoor temperature before clearing snow. Before shut-off, run the attachment a few minutes to prevent impeller freeze-up. NOTICE: Try out each control without the engine running to see how it works and what it does. Manual Start 1. Turn discharge chute straight ahead. 2. Make sure that the attachment clutch and traction drive clutch levers are fully disengaged. 3. Push Primer Bulb 2 or 3 times for cold engine. NOTICE: When temperature is below -15° F (-26° C) additional priming may be needed. 4. If engine is cold, apply choke. See Engine Manual for detailed instructions. NOTICE: A warm engine requires less choking than a cold engine. 5. 920014 - Set throttle to proper starting position. 920013, 021, 022 - Toggle ignition switch to "Run". EN - 21