Bernina 1001 Manual - Page 36

Fault, prevention

|

View all Bernina 1001 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 36 highlights

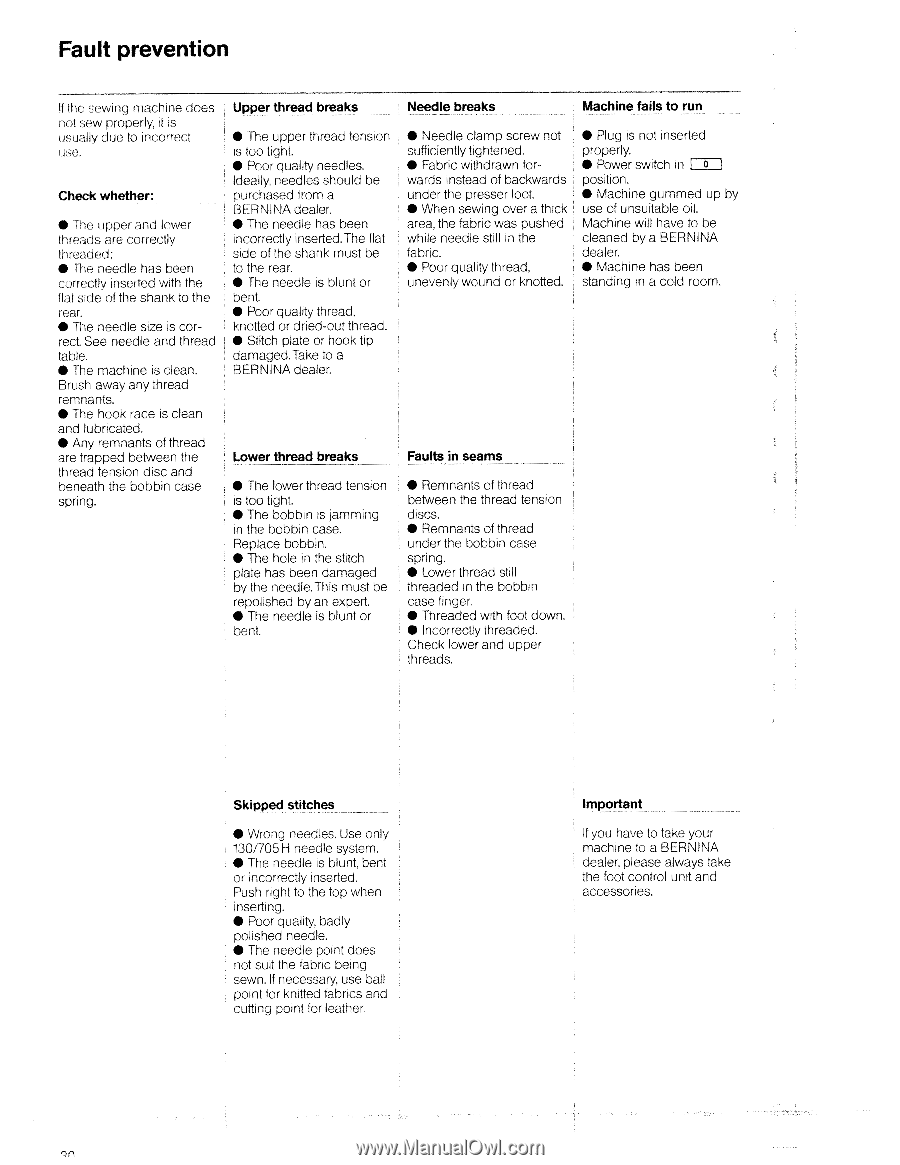

Fault prevention If the sewing machine does not sew properly, it is usually due to incorrect use. Check whether: • The upper and lower threads are correctly threaded; • The needle has been correctly inserted with the flat side of the shank to the rear. • The needle size is correct. See needle and thread table. • The machine is clean. Brush away any thread remnants. • The hook race is clean and lubricated. • Any remnants of thread are trapped between the thread tension disc and beneath the bobbin case spring. Upper thread breaks • The upper thread tension is too tight. • Poor quality needles. Ideally, needles should be purchased from a BERNINA dealer. • The needle has been incorrectly inserted. The flat side of the shank must be to the rear. • The needle is blunt or bent. • Poor quality thread, knotted or dried-out thread. • Stitch plate or hook tip damaged.Take to a BERNINA dealer. Lower thread breaks • The lower thread tension is too tight. • The bobbin is jamming in the bobbin case. Replace bobbin. • The hole in the stitch plate has been damaged by the needle. This must be repolished by an expert. • The needle is blunt or bent. Needle breaks • Needle clamp screw not sufficiently tightened. • Fabric withdrawn forwards instead of backwards under the presser foot. • When sewing over a thick area, the fabric was pushed while needle still in the fabric. • Poor quality thread, unevenly wound or knotted. Faults in seams • Remnants of thread between the thread tension discs. • Remnants of thread under the bobbin case spring. • Lower thread still threaded in the bobbin case finger. • Threaded with foot down. • Incorrectly threaded. Check lower and upper threads. Machine fails to run _ • Plug is not inserted properly. • Power switch in I- 1 position. • Machine gummed up by use of unsuitable oil. Machine will have to be cleaned by a BERNINA dealer. • Machine has been standing in a cold room. Skipped stitches • Wrong needles. Use only 130/705H needle system. • The needle is blunt, bent or incorrectly inserted. Push right to the top when inserting. • Poor quality, badly polished needle. • The needle point does not suit the fabric being sewn. If necessary, use ball point for knitted fabrics and cutting point for leather. Important If you have to take your machine to a BERNINA dealer, please always take the foot control unit and accessories.