Brother International BAS-342G PS Instruction Manual - English - Page 83

range is too great., of the material.

|

View all Brother International BAS-342G PS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 83 highlights

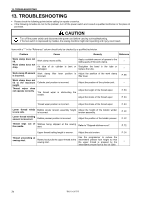

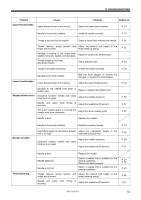

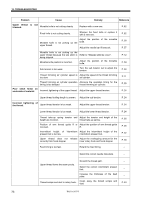

13. TROUBLESHOOTING Problem Cause Remedy Reference Incorrect tightening of the thread. Upper thread trailing length is irregular. Needle is too thin. Damage to the hook stopper. Thread take-up spring tension and height are incorrect. Replace the needle with one with a higher count. Buff the hook stopper to remove the damage, or replace the hook stopper. Adjust the tension and height of the thread take-up spring. * P. 55 Sub tension is too weak. Turn the sub tension nut to adjust the tension. P. 24 Fixed knife is not cutting cleanly. Sharpen the fixed knife or replace it with a new one. Lower thread is protruding from the top of the material. Thread take-up spring tension is too strong. Insufficient thread take-up amount. Adjust the tension of the thread take-up spring. Adjust the position of arm thread guide R. Hitch stitch sewing range is too great. Lower thread tension is too weak. Adjust the lower thread tension. P. 62 P. 55 P. 56 P. 24 Lower thread is threaded incorrectly. Pass the lower thread through the window of the inner rotary hook. P. 23 Sewing speed is too high. Reduce the sewing speed. P. 30 Needle is incorrectly installed. Install the needle correctly. Upper thread position is incorrect. Select the correct intermittent presser foot. Grind the cylinder of the intermittent presser foot so that it does not touch the thread. Needle is shaking. Replace the needle with one with a higher count. Thread trailing length underneath the material is too short. Sewing machine does not operate when the power is turned on and the foot switch is depressed. Fixed knife position is too close to the needle hole plate. Safety switch does not work. Install the fixed knife in the correct position. Check if the safety switch cord is disconnected. Adjust the position of the safety switch. If the safety switch is malfunctioning, replace it with a new one. P. 19 * * P. 62 P. 12 P. 18 * BAS-342G PS 74