Brother International VX-940 Users Manual - English - Page 43

Check, Better, Sewing

|

View all Brother International VX-940 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 43 highlights

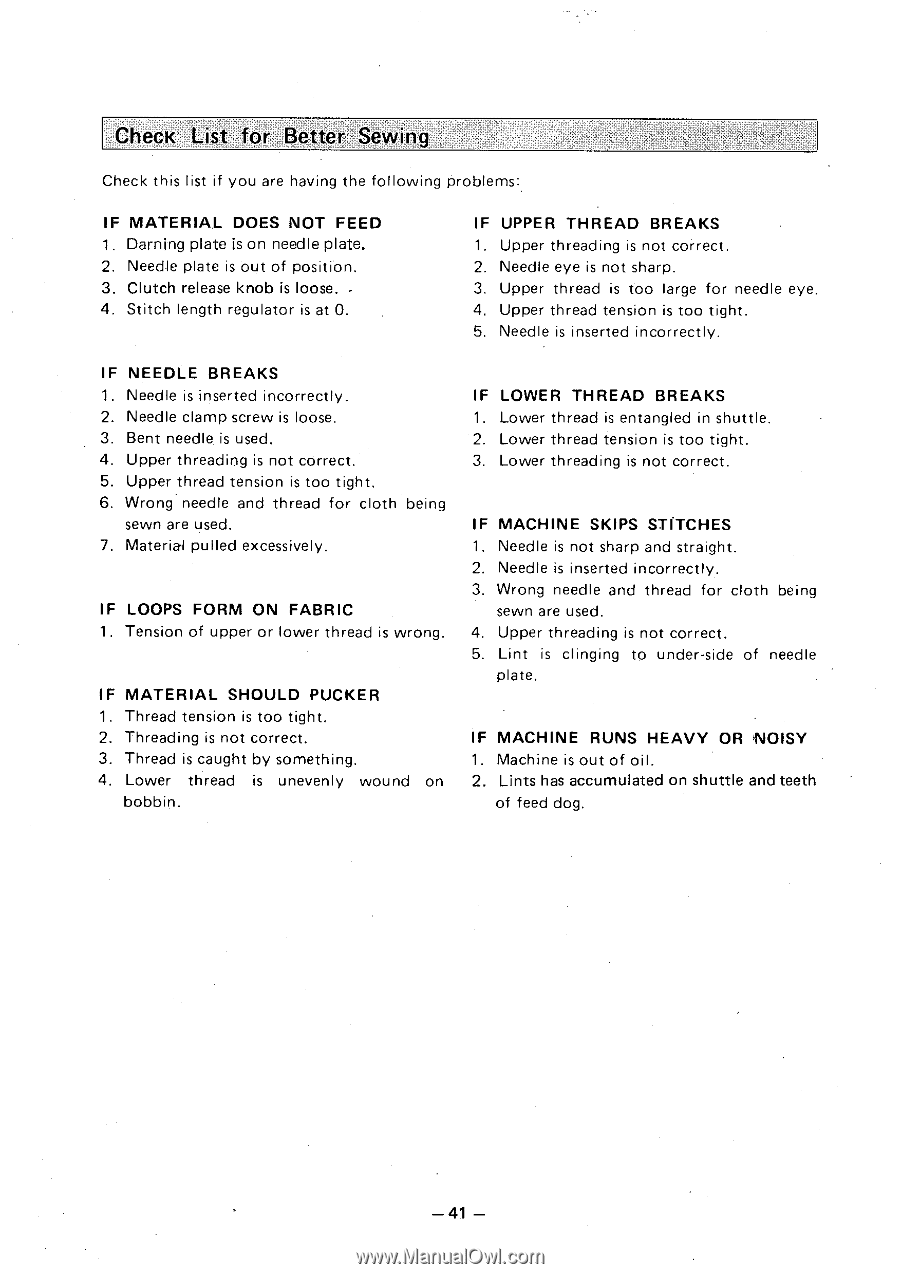

Check List for Better Sewing Check this list if you are having the following problems:. IF MATERIAL DOES NOT FEED 1. Darning plate is on needle plate. 2. Needle plate is out of position. 3. Clutch release knob is loose. 4. Stitch length regulator is at 0. IF UPPER THREAD BREAKS 1. Upper threading is not correct. 2. Needle eye is not sharp. 3. Upper thread is too large for needle eye. 4. Upper thread tension is too tight. 5. Needle is inserted incorrectly. IF NEEDLE BREAKS 1. Needle is inserted incorrectly. 2. Needle clamp screw is loose. 3. Bent needle is used. 4. Upper threading is not correct. 5. Upper thread tension is too tight. 6. Wrong needle and thread for cloth being sewn are used. 7. Material pulled excessively. IF LOOPS FORM ON FABRIC 1. Tension of upper or lower thread is wrong. IF MATERIAL SHOULD PUCKER 1. Thread tension is too tight. 2. Threading is not correct. 3. Thread is caught by something. 4. Lower thread is unevenly wound on bobbin. IF LOWER THREAD BREAKS 1. Lower thread is entangled in shuttle. 2. Lower thread tension is too tight. 3. Lower threading is not correct. IF MACHINE SKIPS STITCHES 1. Needle is not sharp and straight. 2. Needle is inserted incorrectly. 3. Wrong needle and thread for cloth being sewn are used. 4. Upper threading is not correct. 5. Lint is clinging to under-side of needle plate. IF MACHINE RUNS HEAVY OR NOISY 1. Machine is out of oil. 2. Lints has accumulated on shuttle and teeth of feed dog. -41 -