Canon PIXMA MP830 Service Manual - Page 47

In Custom Settings of the MP driver, Waste ink counter setting, White sponge sheet attachment - waste ink absorber

|

View all Canon PIXMA MP830 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 47 highlights

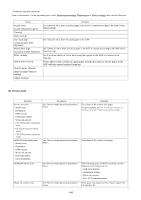

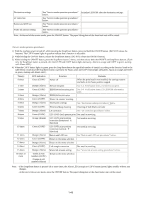

(3) Waste ink counter setting Before replacement of the logic board ass'y, check the waste ink amount. After the logic board ass'y is replaced, set the waste ink amount to the replaced logic board ass'y. In addition, according to the waste ink amount, replace the waste ink absorber (ink absorber kit). When the waste ink absorber is replaced, reset the waste ink counter (to "0%"). How to check the waste ink amount: See 3-4. Verification Items, (1) Service test print, or (2) EEPROM information print. How to set the waste ink amount: See 3-3. Adjustment / Settings, (6) Service mode, "Waste ink amount setting procedures." (4) White sponge sheet attachment Position one of the corners of the white sponge sheet at the scanning reference point on the platen glass (back left where the blue lines cross in the photo below). Peel off the cover sheet from the double-sided adhesive tape, and slowly close the document cover with the sponge frame on. The sponge sheet will attach to the sponge frame. Open the document cover to confirm the following: - No extension of the sponge edges over the mold part of the document cover. - No gap between the platen glass reference edges and the corresponding sponge edges. (5) User mode Function Procedures Remarks Print head manual cleaning See "Standalone machine operation" below, or perform from the MP driver Maintenance tab. Print head deep cleaning See "Standalone machine operation" below, or perform from the MP driver Maintenance tab. Paper feed roller cleaning See "Standalone machine operation" below. Nozzle check pattern printing See "Standalone machine operation" below, or perform from the MP driver Maintenance tab. Print head alignment (automatic / See "Standalone machine operation" below, or manual) perform from the MP driver Maintenance tab. In Custom Settings of the MP driver Maintenance tab, manual print head alignment (by selecting the optimum values) as with the conventional models can be performed. Bottom plate cleaning See "Standalone machine operation" below, or perform from the MP driver Maintenance tab. Cleaning of the platen ribs when the back side of paper gets smeared. Print head replacement The print head is replaceable at the same position as for ink tank replacement. (Open the scanning unit. When the carriage stops at the center, the print head can be replaced.) 1-41