Craftsman 16639 Owners Manual - Page 4

Specifications, Glossary - amps

|

View all Craftsman 16639 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 4 highlights

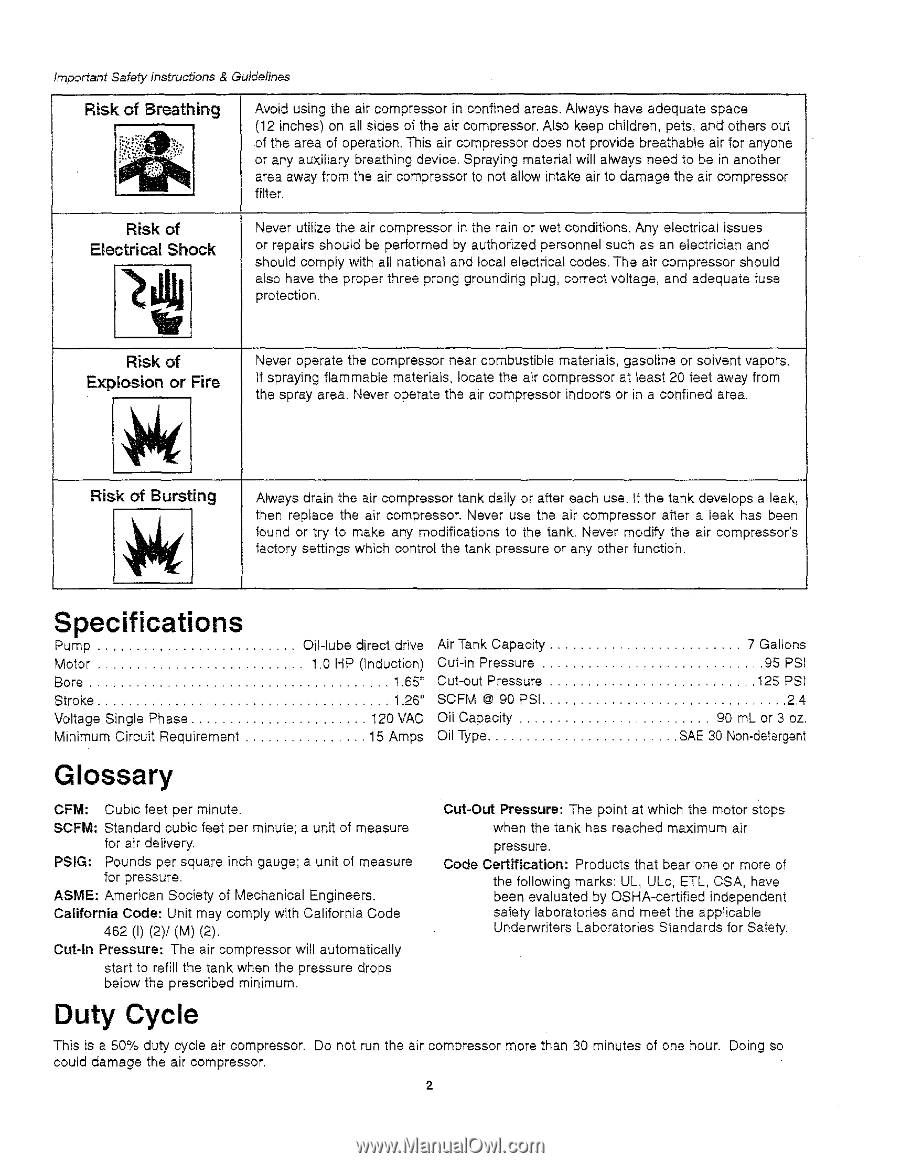

L"np_ant Safely Instructions & Guidelines Risk of Breathing Avoid using the air compressor in confined areas. Always have adequate space (12 inches) on all sides of the air compressor. Also keep children, pets, and others out of the area of operation. This air compressor does not provide breathable air for anyone or any auxiliary breathing device. Spraying matedaTwill always need to be in another area away from the air compressor to net allow intake air to damage the air compressor fitter, Risk of Electrical Shock Never utilize the air compressor in the rain or wet conditions. Any electrical issues or repairs should be performed by authorized personnel such as an electrician and should comply with all national and local electrical codes. The air compressor should also have the proper three prong groundirig plug, correct voltage, and adequate fuse protection. Risk of Explosion or Fire Never operate the compressor near combustible materials, gasoline or solvent vapors. If spraying flammable materials, locate the air compressor at least 20 feet away from the spray area. Never operate the air compressor indoors or in a confined area. Risk of Bursting Always drain the air compressor tank daily or after each use. If the tank develops a leak, then reptace the air compressor. Never use the air compressor after a leak has been found or try to make any modifications to the tank. Never modify the air compressor's factory settings which control the tank pressure or any other function. Specifications Pump Oil-lube direct drive Air Tank Capacity Motor Bore 1.0 HP (Induction) Cut-in Pressure 1.65_ Cut-out Pressure Stroke 126" SCFM @ 90 PSI Voltage Single Phase 120 VAC Oil Capacity Minimum Circuit Requirement 15 Amps Oil Type 7 Gallons 95 PSI 125 PSI 24 90 mL or 3 oz. SAE 30 Non-detergent Glossary CFM: Cubic feet per minute. SCFM: Standard cubic feet per minute; a unit of measure for air delivery. PSIG: Pounds per square inch gauge; a unit of measure for pressure. ASME: American Society of Mechanical Engineers. California Code: Unit may comply with California Code 462 (I) (2)/(U) (2). Cut-In Pressure: The air compressor will automatically start to refill the tank when the pressure drops below the prescribed minimum. Cut-Out Pressure: The point at which the motor stops when the tank has reached maximum air pressure, Code Certification: Products that bear one or more sf the following marks: UL, ULc, ETL, CSA, have been evaluated by OSHA-certified independent safety laboratories and meet the applicable Underwriters Laboratories Standards for Safety. Duty Cycle This is a 50% duty cycle air compressor. Do not run the air compressor more than 30 minutes of one hour. Doing so could damage the air compressor. 2