Craftsman 18180 Operation Manual - Page 5

Operating, Pressure, Contact Trip Adjustment, Exhaust Deflector, Shingle Gauge

|

UPC - 026420181808

View all Craftsman 18180 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

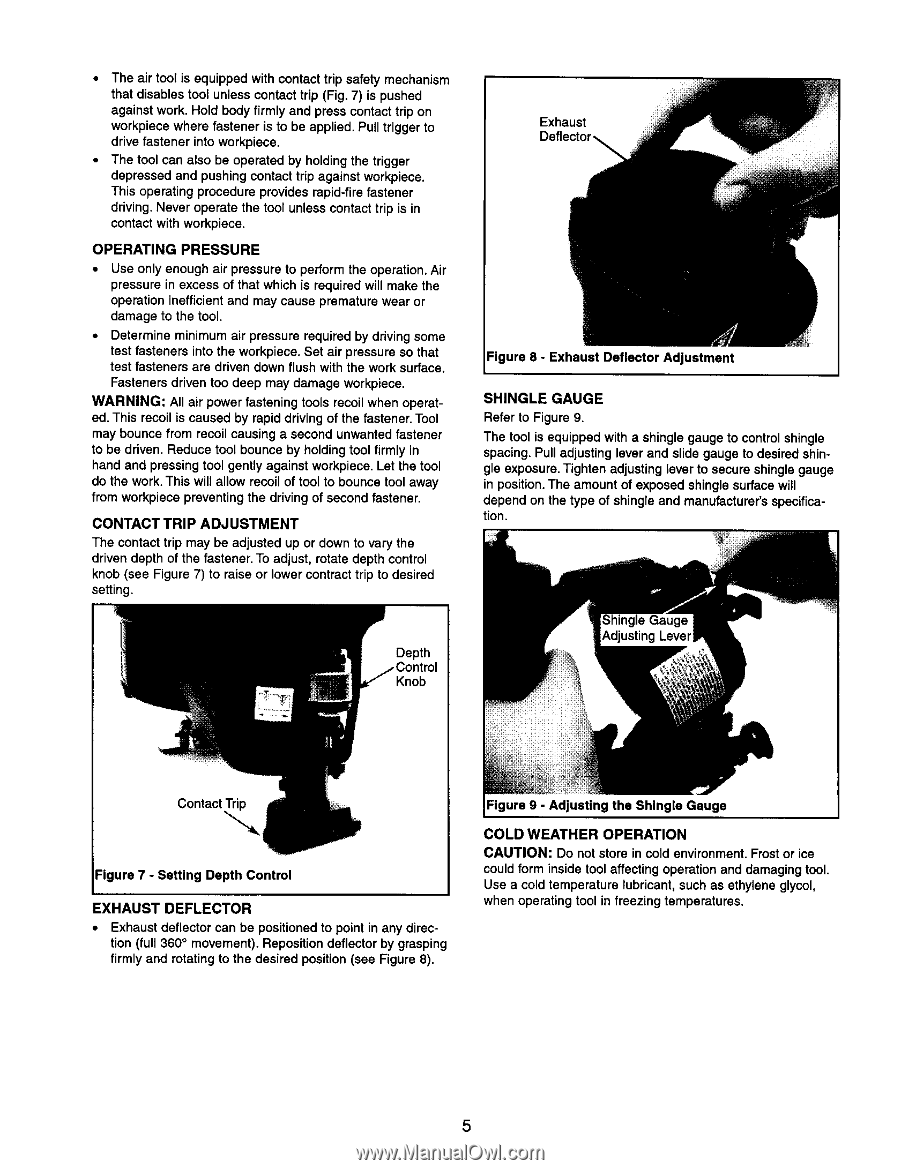

The air tool is equipped with contact trip safety mechanism that disables tool unless contact trip (Fig. 7) is pushed against work. Hold body firmly and press contact trip on workpiece where fastener is to be applied. Pull trigger to drive fastener into workpiece. The tool can also be operated by holding the trigger depressed and pushing contact trip against workpiece. This operating procedure provides rapid-fire fastener driving. Never operate the tool unless contact trip is in contact with workpiece. OPERATING PRESSURE • Use only enough air pressure to perform the operation. Air pressure in excess of that which is required will make the operation inefficient and may cause premature wear or damage to the tool. • Determine minimum air pressure required by driving some test fasteners into the workpiece. Set air pressure so that test fasteners are driven down flush with the work surface. Fasteners driven too deep may damage workpiece. WARNING: All air power fastening tools recoil when operated. This recoil is caused by rapid driving of the fastener. Tool may bounce from recoil causing a second unwanted fastener to be driven. Reduce tool bounce by holding tool firmly in hand and pressing tool gently against workpiece. Let the tool do the work.This will allow recoil of tool to bounce tool away from workpiece preventing the driving of second fastener. CONTACT TRIP ADJUSTMENT The contact trip may be adjusted up or down to vary the driven depth of the fastener. To adjust, rotate depth control knob (see Figure 7) to raise or lower contract trip to desired setting. Exhaust Deflector Figure 8 - Exhaust Deflector Adjustment SHINGLE GAUGE Refer to Figure 9. The tool is equipped with a shingle gauge to control shingle spacing. Pull adjusting lever and slide gauge to desired shingle exposure. Tighten adjusting lever to secure shingle gauge in position.The amount of exposed shingle surface will depend on the type of shingle and manufacturer's specification. Depth Knob Contact Trip ""-i ure 7 - Setting Depth Control EXHAUST DEFLECTOR • Exhaust deflector can be positioned to point in any direc- tion (full 360° movement). Reposition deflector by grasping firmly and rotating to the desired position (see Figure 8). Figure 9 - Adjusting the Shingle Gauge COLD WEATHER OPERATION CAUTION: Do not store in cold environment. Frost or ice could form inside tool affecting operation and damaging tool. Use a cold temperature lubricant, such as ethylene glycol, when operating tool in freezing temperatures. 5