Craftsman 18180 Operation Manual - Page 6

Lubrication, Rebuild Kits

|

UPC - 026420181808

View all Craftsman 18180 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

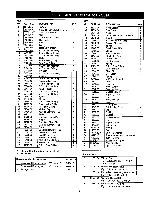

Refer to Figure 10. LUBRICATION Lubricate tool daily with quality air tool oil. If no air line lubricator is used, place five or six drops of oil into air inlet cap (Figure 10, Key No. 33) of tool everyday. MAGAZINE AND PISTON-RAM • Keep magazine and nose of tool clean and free of any dirt, lint or abrasive particles. The tip of the ram (Figure 10, Key No. 16) can become dented or rounded over time. • Square off the tip of the ram with a clean, fine hand file to extend the life of the ram and tool. Fastener firing will be more consistent if the ram tip is kept clean and square. SAFETY MECHANISM CHECK Inspect contact trip safety mechanism daily for proper operation. Do not operate tool if mechanism is not operating properly. Perform the following procedures to test safety mechanism: • Leave trigger untouched while pushing contact trip into workpiece. Tool must not fire. • Pull trigger while contact trip is clear of work and pointed away from operator and others. Tool must not fire. • Depress and hold trigger. Push contact trip against work where fastener is needed. The tool should drive only one fastener each time the contact trip is pushed against workpiece. If contact trip mechanism does not operate properly, repair tool immediately through Sears Service Center. Replace any damaged or missing parts. Use the parts list to order parts. REBUILD KITS Rebuild kits are available as spare parts, (see page 9). Tools should be rebuilt if tool fails to operate properly after extended use. See troubleshooting to determine required replacement parts. Disconnect tool from air supply before attempting repair or adjustment. NOTE: When replacing O-rings or cylinder, lubricate with grease before assembly, 6