Craftsman 21154 Owners Manual - Page 9

LIGHT - Provides - variable speed 6 grinding center

|

View all Craftsman 21154 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

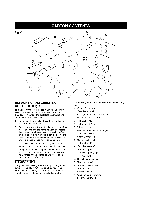

16 \ 17 \18 2 14 13 12 11 10 1. INNER WHEEL GUARD - Covers the grinding wheels and protects against accidental contact. 2. WHEEL DRESSER - Used to clean and smooth front surface of the grinding wheels. 3. FLEXIBLE WORK LIGHT - Provides light to the operator during set up or grinding operations. 4. SPARK ARRESTOR - Prevents hot sparks and debris from contacting the operator. 5. QUICK RELEASE KNOB - Remove knobs to allow the Wheel Cover to be removed. 6. WHEEL COVER - Covers the grinding wheels and provides quick access for routine maintenance. 7. GRINDING WHEEL 60 GRIT - Used to remove light material from workpiece. 8. TOOL RESTS - Used to support the workpiece that is being ground. Adjustable to provide angled surfaces. 9. DRILL BIT SHARPENING PLATE - Used to sharpen twist drill bits. Should be removed for regular grinding operations. 10. ON/OFF SWITCH - Used to turn ON and turn OFF the grinder. 11. VARIABLE SPEED SWITCH - Permits adjusting rotational speed of the grinding wheel. 12. QUENCH TRAY - Used to cool workpiece after grinding. 13. TOOL REST ADJUSTABLE SUPPORTS - Lets the operator position the tool rest closer to the wheel as the wheel decreases in diameter due to wear. 14. 6" WIRE WHEEL - Used to remove rust and dirt from workpiece. 15. EYESHIELD - Protective Lexan see-thru shields to prevent any loose debris from contacting the operator. 16. GRINDING WHEEL IDENTIFICATION LABEL Provides information on wheel size, grit and maximum rpm. 17. FLANGES - used to secure the grinding wheels to the grinder and distribute the load of the Lock Nuts. 18. ARBOR HEX NUT - Used to secure the grinding wheels to the grinder. 19. SPACER (not shown) - Used to align the wire wheel or buffing wheel into the center of the tool rest.