Craftsman 26302 Operation Manual - Page 18

Fig, 8

|

UPC - 009263020008

View all Craftsman 26302 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

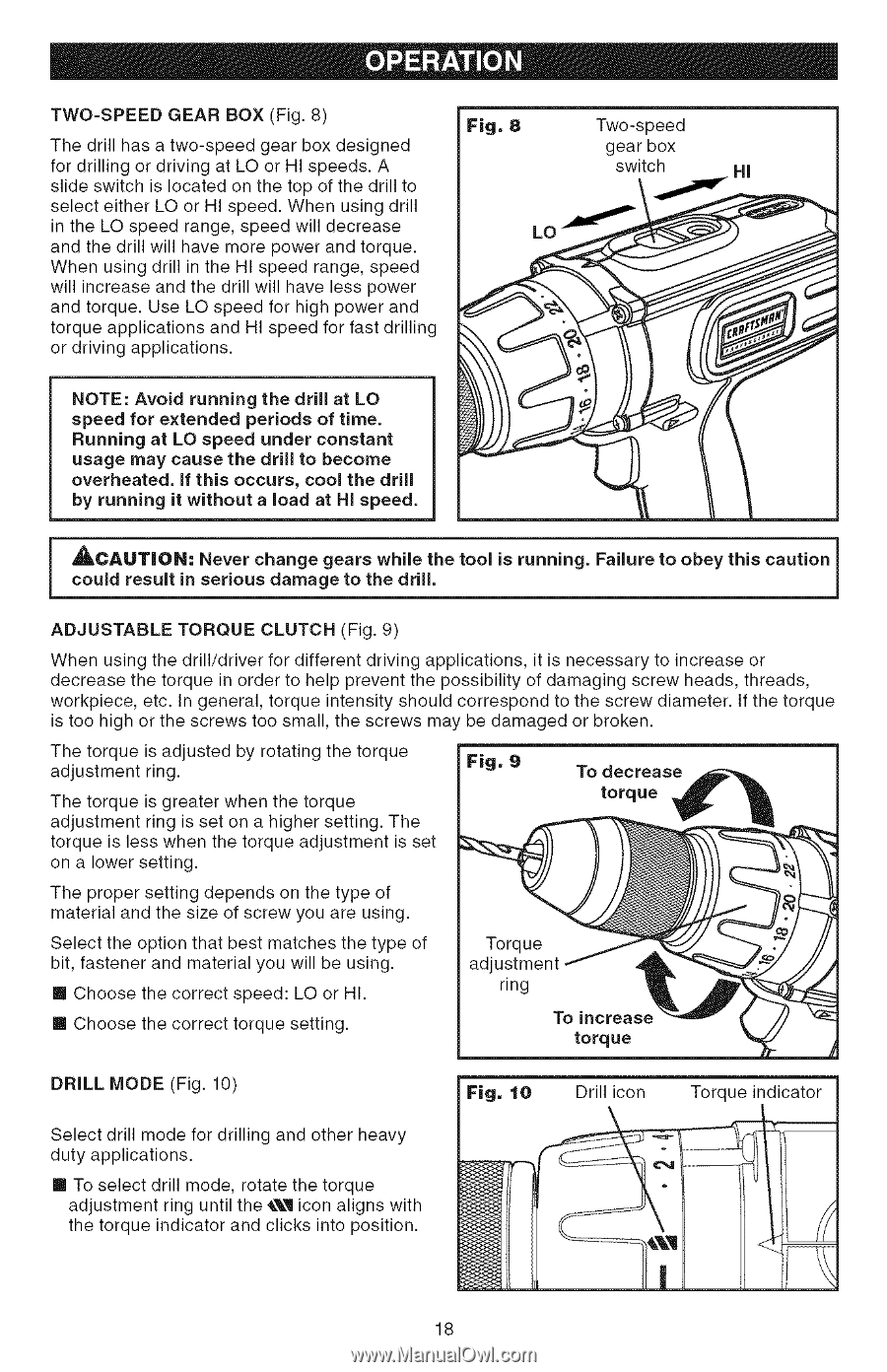

TWO-SPEGEEDARBOX(Fig8. ) Thedrilhl asatwo-spegeedabr oxdesigned fordrillinogrdrivinagtLOorHIspeedAs. slideswitcihslocateodnthetopofthedriltlo selecteither LO or HI speed. When using drill in the LO speed range, speed will decrease and the drill will have more power and torque. When using drill in the HI speed range, speed will increase and the drill will have less power and torque. Use LO speed for high power and torque applications and HI speed for fast drilling or driving applications. Fig, 8 NOTE: Avoid running the drill at LO speed for extended periods of time. Running at LO speed under constant usage may cause the drill to become overheated, if this occurs, cool the drill by running it without a load at HI speed. Two-speed gearbox switch Hi _CAUTION: Never change gears while the tool is running. Failure to obey this caution/ could result in serious damage to the drill. ! ADJUSTABLE TORQUE CLUTCH (Fig. 9) When using the drill/driver for different driving applications, it is necessary to increase or decrease the torque in order to help prevent the possibility of damaging screw heads, threads, workpiece, etc. In general, torque intensity should correspond to the screw diameter, if the torque is too high or the screws too small, the screws may be damaged or broken. The torque is adjusted by rotating the torque adjustment ring. The torque is greater when the torque adjustment ring is set on a higher setting. The torque is less when the torque adjustment is set on a lower setting. Fig, 9 To decrease torque The proper setting depends on the type of material and the size of screw you are using. Select the option that best matches the type of bit, fastener and material you will be using. Ill Choose the correct speed: LO or HI. ill Choose the correct torque setting. Torque adjl ring To increase torque DRILL MODE (Fig. 10) Select drill mode for drilling and other heavy duty applications. ill To select drill mode, rotate the torque adjustment ring until the _.&._icon aligns with the torque indicator and clicks into position. Fig, t0 Drillicon Torque indicator 18