Craftsman 30084N Operation Manual - Page 10

Installing Work Clamp, Installing Gas Supply - tools

|

UPC - 055249070420

View all Craftsman 30084N manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 10 highlights

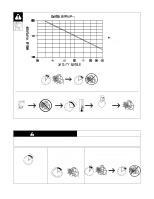

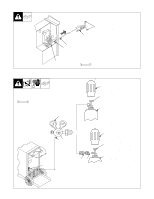

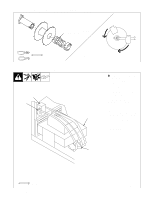

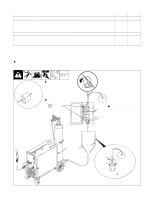

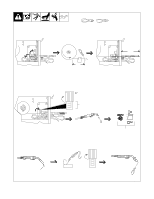

2-5. Installing Work Clamp 1 2 4 5 1 Work Cable 2 Boot Slide boot onto work cable. Route cable out front panel opening from inside. 3 Negative (-) Output Terminal Connect cable to terminal and cover connection with boot. 4 Hardware 5 Work Clamp Route cable through clamp handle and secure as shown. Close door. 3 2-6. Installing Gas Supply Tools Needed: 5/8, 1-1/8 in 4 7 5 6 Tools Needed: 1/2, 3/4 in ST-801 566-A OR 8 1 2 3 Argon Gas 1 2 3 9 CO2 Gas Obtain gas cylinder and chain to running gear, wall, or other stationary support so cylinder cannot fall and break off valve. 1 Cap 2 Cylinder Valve Remove cap, stand to side of valve, and open valve slightly. Gas flow blows dust and dirt from valve. Close valve. 3 Cylinder 4 Regulator/Flowmeter Install so face is vertical. 5 Regulator/Flowmeter Gas Hose Connection 6 Welding Power Source Gas Hose Connection Connect customer supplied gas hose between regulator/flowmeter gas hose connection, and fitting on rear of welding power source. 7 Flow Adjust Typical flow rate is 20 cfh (cubic feet per hour). Check wire manufacturer's recommended flow rate. 8 CO2 Adapter (Customer Supplied) 9 O-Ring (Customer Supplied) Install adapter with O-ring between regulator/flowmeter and CO2 cylinder. OM-194 199 Page 7 ST-801 571 / ST-802 028