Craftsman 30084N Operation Manual - Page 21

Replacing Gun Contact Tip, Troubleshooting

|

UPC - 055249070420

View all Craftsman 30084N manuals

Add to My Manuals

Save this manual to your list of manuals |

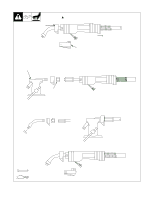

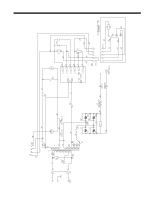

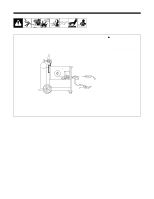

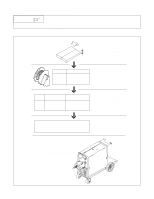

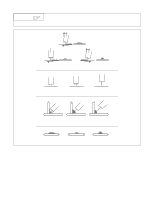

Page 21 highlights

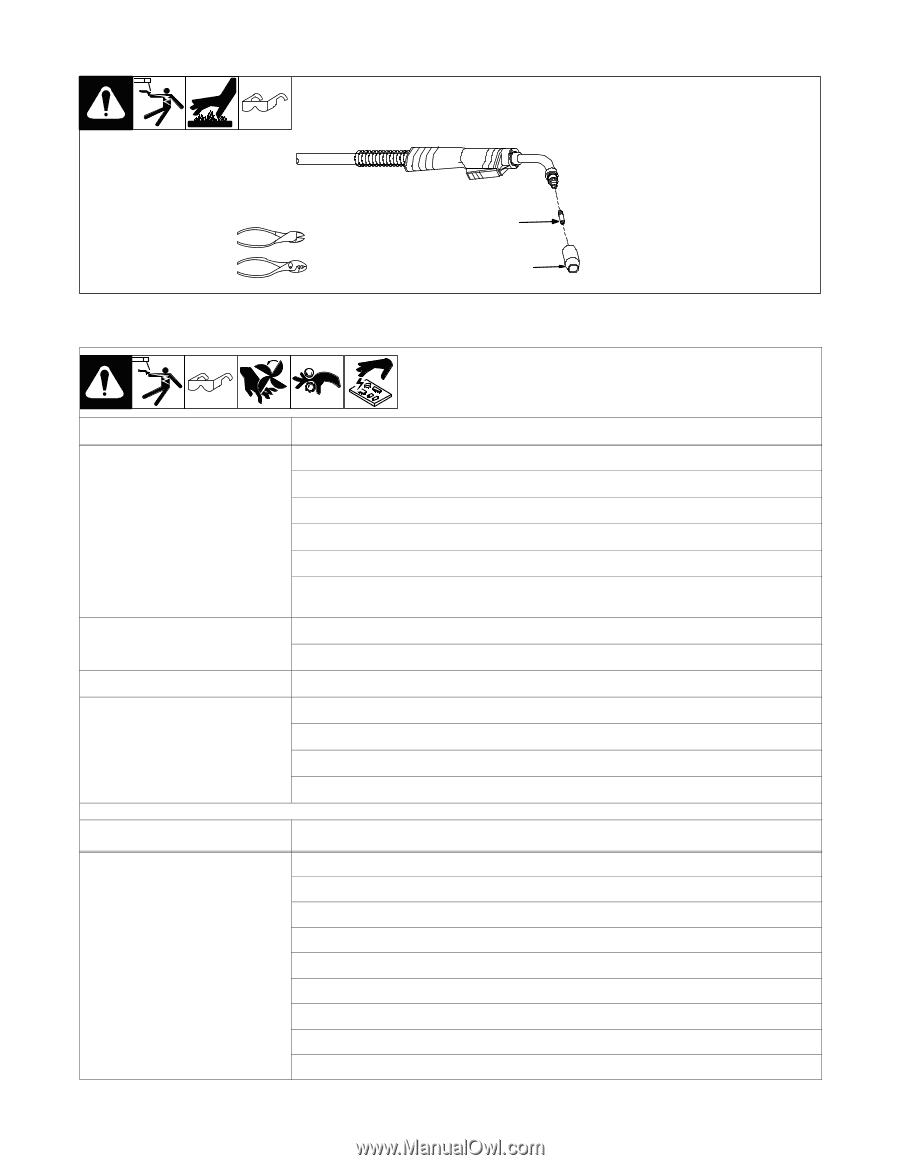

4-6. Replacing Gun Contact Tip Tools Needed: 4-7. Troubleshooting Y Turn Off unit. 1 Nozzle 2 Contact Tip Cut off welding wire at contact tip. Remove nozzle. Remove contact tip and install new contact tip. Reinstall nozzle. 2 1 Ref. 800 797-C Welding Trouble No weld output; wire does not feed. No weld output; wire feeds. Low weld output. Low, high, or erratic wire speed. Remedy Secure power cord plug in receptacle (see Section 2-12). Check and replace power switch if necessary. Check circuit breakers CB1 and/or CB2, and reset if necessary (see Section 4-2). Replace building line fuse or reset circuit breaker if open (see Section 2-12). Secure gun plug in receptacle or repair leads, or replace trigger switch (see Section 2-7 and/or 4-5). Thermostat TP1 open (overheating). Allow fan to run; the thermostat will close when the unit has cooled (see Section 2-3). Connect work clamp to get good metal to metal contact. Replace contact tip (see Section 4-6). Connect unit to proper input voltage or check for low line voltage (see Section 2-12). Readjust front panel settings (see Section 3-1). Change to correct size drive roll (see Section 11-3). Readjust drive roll pressure (see Section 2-13). Replace inlet guide, contact tip, and/or liner if necessary (see Sections 4-3, and 4-4). Wire Drive/Gun Trouble Remedy Electrode wire feeding stops during Straighten gun cable and/or replace damaged parts (see Section 4-4). welding. Adjust drive roll pressure (see Section 2-13). Readjust hub tension (see Section 2-9). Replace contact tip if blocked (see Section 4-6). Clean or replace wire inlet guide or liner if dirty or plugged (see Section 4-4). Replace drive roll if worn or slipping (see Section 11-3). Secure gun plug in receptacle or repair leads, or replace trigger switch (see Section 2-7 and/or 4-5). Check and clear any restrictions at drive assembly and liner (see Section 4-4). Have nearest Factory Authorized Service Agent check drive motor. OM-194 199 Page 18