Cub Cadet GTX 2100 GTX 2100 Operator's Manual - Page 21

Adjustments - cadet

|

View all Cub Cadet GTX 2100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

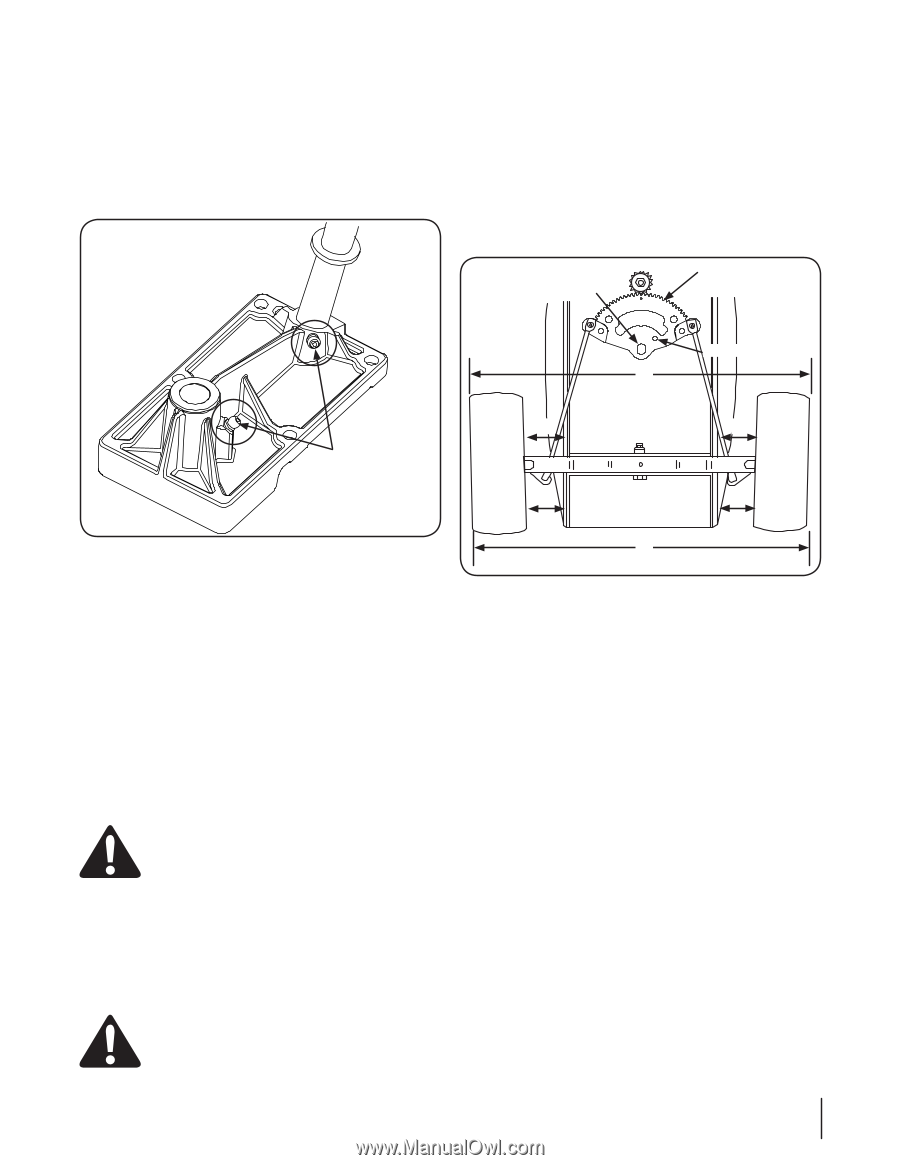

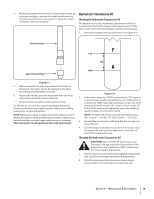

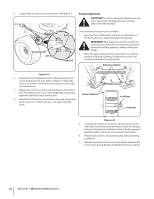

Steering Housing & Steering Shaft The steering housing and steering shaft should be lubricated after every 25 hour of operation. To access the lube fittings, proceed as follows: 1. Raise the tractor's hood. 2. Locate the grease fitting for the steering housing and steering shaft under the battery. See Figure 6-5. Parking Brake Adjustment If the tractor does not come to a complete stop when the brake pedal is completely depressed, or if the tractor's rear wheels can roll with the parking brake applied (and the hydrostatic relief valve open), the brake is in need of adjustment. See your Cub Cadet dealer to have the brake adjusted. Wheel Alignment The front wheels should toe-in approximately 1⁄8 to 1⁄4", as measured across dimensions A and B. See Figure 6-6. Pivot Hole Steering Gear Centered Centering Hole A C C Grease Fittings D D Figure 6-5 3. Using a pressure lubricating gun, apply 251H EP grease, or an equivalent No. 2 multipurpose lithium grease, through the grease fittings. 4. Close the tractor hood Deck Wheels Each of the tractor deck's gauge wheels is equipped with a grease fitting. Lubricate with a No. 2 multi-purpose grease applied with a grease gun after every 25 hours of tractor operation. Pivot Points & Linkage Lubricate all the pivot points on the drive system, parking brake and lift linkage at least once a season with light oil. Adjustments WARNING! Shut the engine off, remove the ignition key and engage the parking brake before making adjustments. Protect your hands by using heavy gloves when handling the blades. NOTE: Check the tractor's tire pressure before performing any deck leveling adjustments. Refer to Tires on page 10 for information regarding tire pressure. Seat Adjustment Refer to the Assembly & Set-Up section of this manual for seat adjustment instructions. WARNING! Before operating the tractor, make sure the seat is engaged in the seat-stop. Engage the parking brake. Stand behind the machine and pull back on seat until it clicks into place. B Figure 6-6 Steering/Toe-in Adjustment To adjust front wheel toe-in, proceed as follows: 1. Check the steering gear to ensure it is in the centered position. The hole in the steering segment gear will align with the hole in the steering housing (See Figure 6-6). NOTE: A 5⁄16" pin can be used in the alignment holes to assure the steering segment is centered. 2. Mark the front horizontal diameter of both front wheels at the same spot on each wheel-preferably the inner bead flange of the wheel rims. Mark the rear horizontal diameter of both front wheels in the same manner. 3. Measure the distance between the bottom edges of the tractor frame channels and the marks on the front of each wheel (See measurement D in Figure 6-6). These two measurements should be equal. 4. Measure the distance between the frame and the marks on the rear of each front wheel (See measurement C in Figure 6-6). Measurement D should be approximately 1⁄16- to 1⁄8inch less than measurement C on each side of the tractor. Section 6 - Maintenance & Adjustments 21