Kenmore 7560 Installation Instructions - Page 3

Before Starting - range installation instructions

|

View all Kenmore 7560 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

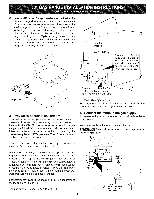

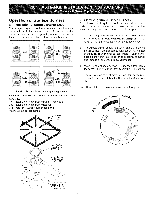

Before Starting Tools You Will Need For leveling legs and Anti-Tip Bracket: Adjustable wrench or channel lock pliers • 5/16" NutdrJver or Flat Head Screw Driver _J Electric Drill & 1/8" Diameter Drill Bit (5/32" Masonry Drill Bit if installing in concrete) For gas supply connection: = Pipe wrench For burner flame adjustment: • Phillips head and blade-type screwdrivers For gas conversion (LP/Propane or Natural): • Open end wrench - 1/2" _:_", _ Additional Materials You Will Need Gas line shut-off valve _.,._, • Pipe joint sealant that resists action of LP/Propane gas A new flexible metal appliance conduit (1/2" NPT x 3/4" or 1/2" kD.) must be design certified by CSA International. Because solid pipe restricts moving the range we recommend using a new flexible conduit (4 to 5 foot length) for each new installation and additional reinstallations. A. Locate the Bracket Using the Template- (Bracket may be located on either the left or right side of the range. Use the information below to locate the bracket if template is not available). Mark the floor or wall where left or right side of the range will be located. If rear of range is against the wall or no further than 1-1/4" from wall when installed, you may use the wall or floor mount method. If molding is installed and does not allow the bracket to fit flush against the wall, remove molding or mount bracket to the floor. For wall mount, locate the bracket by placing the back edge of the template against the rear wall and the side edge of template on the mark made referencing the side of the range. Place bracket on top of template and mark location of the screw holes in wall. If rear of range is further than 1-1/4" from the wall when installed, attach bracket to the floor. For floor mount, locate the bracket by placing back edge of the template where the rear of the range will be located. Mark the location of the screw holes, shown in template. B. Drill Pilot Holes and Fasten Bracket - Drill a 1/8" pilot hole where screws are to be located. If bracket is to be mounted to the wall, drill pilot hole at an approximate 20 ° downward angle. If bracket is to be mounted to masonry or ceramic floors, drill a 5/32" pilot hole 1-3/4" deep. The screws provided may be used in wood or concrete material. Use a 5/16" nut-driver or flat head screwdriver to secure the bracket in place. Always use the (2) new flare union adapters (1/2" NPTx 3/4" or 1/2" I.D.) supplied with the new flexible appliance conduit for connection of the range. Normal Installation Steps 1. Anti-Tip Bracket Installation Instructions Important Safety Warning To reduce the risk of tipping of the range, the range must be secured to the floor by properly installed anti-tip bracket and screws packed with the range. Failure to install the anti-tip bracket will allow the range to tip over if excessive weight is placed on an open door or if a child climbs upon it. Serious injury might result from spilled hot liquids or from the range itself. If range is ever moved to a different location, the anti-tip brackets must also be moved and installed with the range. Instructions are provided for installation in wood or cement fastened to either the floor or wall. When installed to the wall, make sure that screws completely penetrate dry wall and are secu red in wood or metal. When fastening to the floor or wall, be sure that screws do not penetrate electrical wiring or plumbing. FASTEN BRACKET (FLOOR MOUNT|NG ONLY)