KitchenAid KPCG100OB Use & Care Guide - Page 30

Replacing the Cutting Burrs

|

UPC - 883049061917

View all KitchenAid KPCG100OB manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 30 highlights

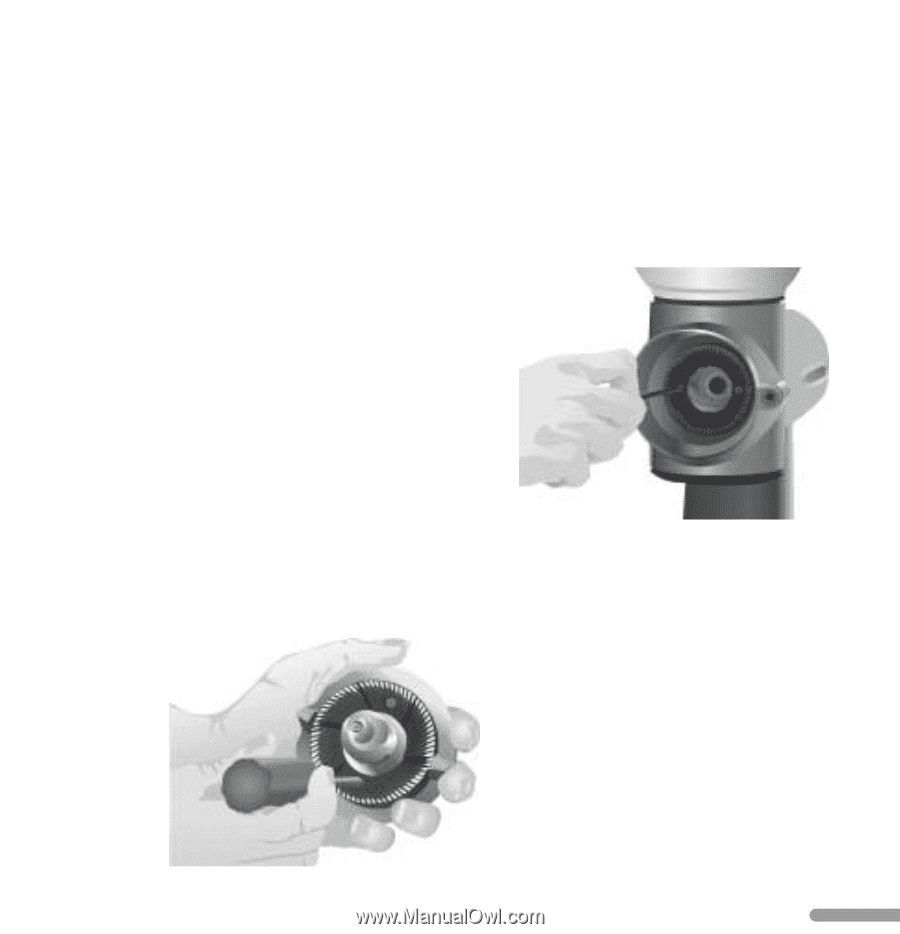

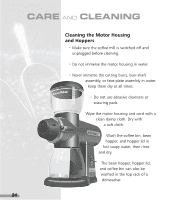

Replacing the Cutting Burrs If the cutting burrs are damaged, or have reached the end of their life (usually after grinding 600-800 lbs. of coffee), they can be replaced easily. Contact KitchenAid at 1-800-541-6390 to order a set of replacement burrs. 3. Remove the burr from the motor housing by turning the two burrmounting screws counter-clockwise until free. CARE AND CLEANING To replace the burrs: 1. Remove the faceplate and burr-shaft assemblies. For instructions, see "Cleaning the Cutting Burrs" steps 1, 2, and 3 on pages 25 and 26. 2. With a Phillips screwdriver, remove the burr from the burr-shaft assembly by turning the two burr-mounting screws counter-clockwise until free. 4. Attach the replacement burrs to the burr-shaft assembly and motor housing using the burr-mounting screws. Make certain the cutting surfaces of the burrs face outward, and the burr-mounting screws are tight. 5. Insert the burr-shaft assembly into the motor housing and attach the faceplate assembly. For instructions, see "Cleaning the Cutting Burrs" steps 5 - 10 on pages 27 and 28. 29