LiftMaster LMSC1000 Installation Manual - English French Spanish - Page 6

Troubleshooting, Programming Your LiftMaster tags into myQ, Business

|

View all LiftMaster LMSC1000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

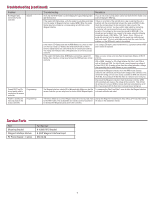

Programming Your LiftMaster tags into myQ® Business™ When adding a new credential in myQ® Business™, go to the credentials tab, click "Add new credentials" and when selecting type, choose RFID_Tags_LiftMaster. Troubleshooting Problem Reader does not read tags (Reader LED is Red and does not change) Reader reads RFID tags however not at an adequate range. (The average read range should be 20-25') Power Programming Final Power RFID Tags Outside Interference Programming Troubleshooting Resolution Check the power supply voltage at the closest termination to the reader If the wiring distance and gauge are correct and the supply is 12V DC. Measure the wiring distance between the reader (mounted) and where the power supply plugs in to the main power source. This distance should not exceed 50'. Check the wiring gauge to make sure it is within specification for this product (Cat5/6 should never be used for power). If the above all checks out and the reader recovers with a power cycle to both reader and Wiegand module then investigate the main (115VAC) supply. If the main power source experiences a brown out condition (voltage drops below 100VAC but does not go away entirely), this may lock up the reader and cause it to malfunction. Switch to a separate main power (115VAC) source or install a UPS system to provide a more stable power source. Remove the serial connector (green, white and yellow wires from reader) from the Wiegand interface module and cycle power to both devices. If the reader regains normal function then the issue may be in the Wiegand interface module. The Wiegand interface has a arming loop feature that will place the RFID reader into standby mode when the loop input is not active. Check the arming loop setting of the Wiegand interface module on dip switch S1-5 and make sure this switch is in the off position. If the setting is off and the problem persists, replace the Wiegand interface module. If the reader does not recover after a power cycle and the above troubleshooting does not reveal the problem, there may be an issue internally in the reader. Contact your channel partner and request an RMA to send in the reader for repair or order a replacement. Check the power supply voltage at the closest termination to the reader (typically at the Wiegand interface module) with a DMM. You should read >12V DC. Measure the wiring distance between the reader (mounted) and where the power supply plugs in to the main power source. This distance should not exceed 50'. There is a direct correlation between the quality of the power supplied to the reader and the reader range. Make sure that the wiring distance is kept to minimum (no coiled wire), gauge is correct and the supply is >12V DC. If all checks out proceed to the next section under programming. Check the wiring gauge to make sure it is within specification for this product (Cat5/6 should never be used for power). You will not experience normal operating range if you are testing windshield/headlamp mount tags by hand. The tags need the intended mounting surface to achieve normal operating range. Temporarily mount the tag to intended surface using tape and retest. Inspect the mounting of the RFID tags and make sure they are mounted Consult the RFID tag installation manual and make sure that the tags are correctly and away from any interference sources. mounted correctly. RFID readers are susceptible to interference from other electronic devices and environmental conditions. Make sure the reader has free line of sight to the RFID tag on the vehicle in the road way. It cannot be obstructed in any way by foliage (plants, bushes, and trees) or metal (posts, signs, gate arms). Remove any obstructions that are in front of the reader's read zone. Check the area around the installation for other electronic devices that may emit noise and interference such as high voltage power lines, florescent lights, cell phone towers, high power UHF radio transmitters or antennas (Including other RFID systems). Investigate if any of these sources can be temporarily disabled to allow RFID reader testing. If the RFID reader range increases when the device is disabled then you have located the source of interference. You may need to relocate the interference source or RFID reader. This reader offers a range adjustment on the Wiegand interface module. Confirm the read range setting using the steps in the installation manual. This default sets the reader range at maximum however this may have changed. 6