LiftMaster T T- Mechanical New style with thermal overload Manual - Page 11

Brake Adjustment, Maintenance Schedule, How To Order Repair Parts - technical support

|

View all LiftMaster T manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

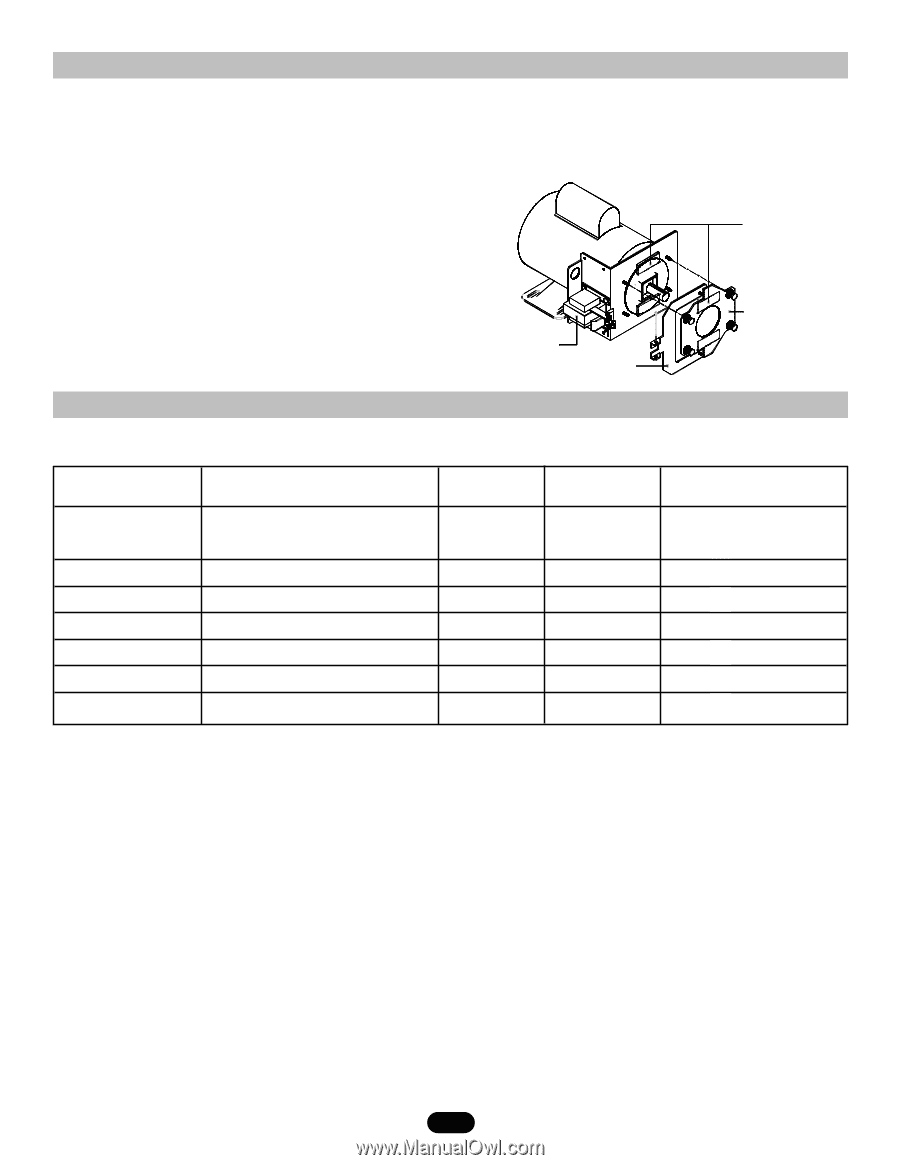

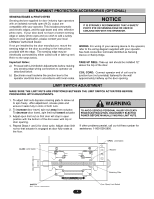

BRAKE ADJUSTMENT A solenoid brake is standard on 3/4 and 1 horsepower models, and is optional on 1/3 and 1/2 horsepower models. The brake is adjusted at the factory and should not need additional adjustment for the the life of the friction pad. Replace friction pads when necessary. Refer to the illustration for identification of components for the solenoid type brake system. Solenoid Brake System Friction Pads Solenoid Release Lever MAINTENANCE SCHEDULE Check at the intervals listed in the following chart. Plate Assembly ITEM Drive Chain Sprockets Clutch Belt Fasteners Manual Disconnect Bearings & Shafts PROCEDURE Check for excessive slack. Check & adjust as required. Lubricate.* Check set screw tightness Check & adjust as required Check condition & tension Check & tighten as required Check & Operate Check for wear & lubricate EVERY 3 MONTHS $ $ $ EVERY 6 MONTHS $ $ $ $ EVERY 12 MONTHS %" Use SAE 30 Oil (Never use grease or silicone spray). Repeat ALL procedures. # Do not lubricate motor. Motor bearings are rated for continuous operation. # Do not lubricate clutch or V-belt. # Inspect and service whenever a malfunction is observed or suspected. # CAUTION: BEFORE SERVICING, ALWAYS DISCONNECT OPERATOR FROM POWER SUPPLY. HOW TO ORDER REPAIR PARTS OUR LARGE SERVICE ORGANIZATION SPANS AMERICA INSTALLATION AND SERVICE INFORMATION IS AS NEAR AS YOUR TELEPHONE SIX DAYS A WEEK. SIMPLY WHEN ORDERING REPAIR PARTS, ALWAYS GIVE THE FOLLOWING INFORMATION: • PART NUMBER • PART NAME • MODEL NUMBER DIAL OUR TOLL FREE NUMBER: 1-800-528-2806 HOURS: (Central Standard Time) ADDRESS ORDERS TO: THE CHAMBERLAIN GROUP, INC. Technical Support Group 6:00 A.M. TO 7:00 P.M. - Monday through Friday 8:00 A.M. TO 4:30 P.M. - Saturday www.liftmaster.com 6020 S. Country Club Road Tucson, Arizona 85706 11