Makita MAC5501G Instruction Manual - Page 16

Trouble Shooting - replacement parts

|

View all Makita MAC5501G manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 16 highlights

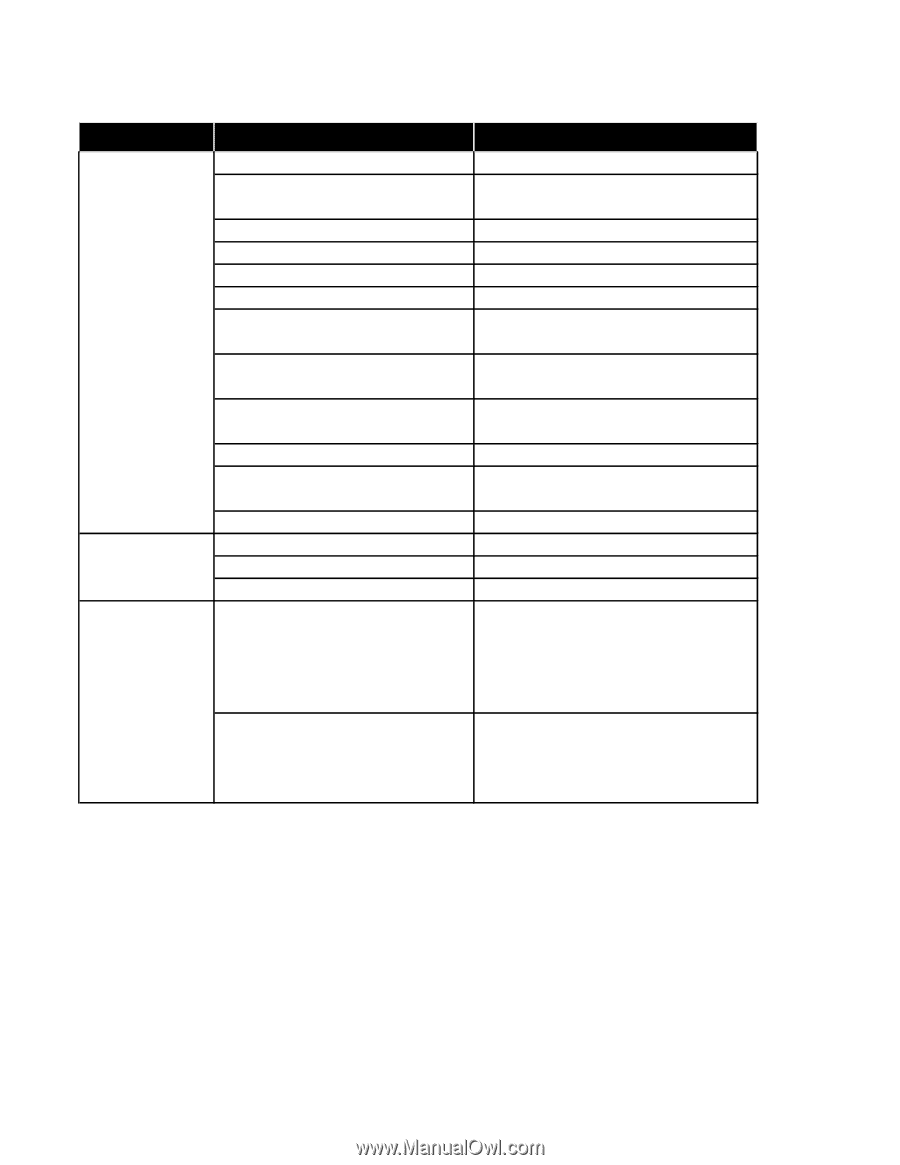

TROUBLE SHOOTING PROBLEM Insufficient output, low discharge pressure Engine stalls Water in crankcase oil gets dirty, rusty valves or cylinders POSSIBLE CAUSE Clogged inlet filter Leaks in air lines, air valves, fittings, etc. Drive belts slipping. Drain valve left open Defective pressure gauge Leaking head gasket Dirty or plugged inter cooler tubes Unloader pilot adjusted too low, or defective Worn or defective compressor valves Worn piston work out rings Restrictive check valve Compressor incorrectly sized Faulty unloader / check valve Low oil in engine Compressor not level Cycle too short; compressor does not operate long enough to vaporize condensed moisture during compression Compressor operating outside in cold conditions or inlet filter not protected against weather CORRECTIVE ACTION Clean or replace as necessary Replace worn components as necessary Tension V-belts Close drain valve Replace pressure gauge Replace head gasket Remove and clean inter cooler tubes Make necessary adjustments Replace valves Replace worn parts Clean check valve and replace if necessary Upgrade to larger compressor Replace unloader check valve Add oil to engine Level compressor Allow for longer operating cycle Provide adequate protection against extreme weather conditions Page 16