Pfaff 332 Owner's Manual - Page 18

Dit,1tant, 9acts

|

View all Pfaff 332 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

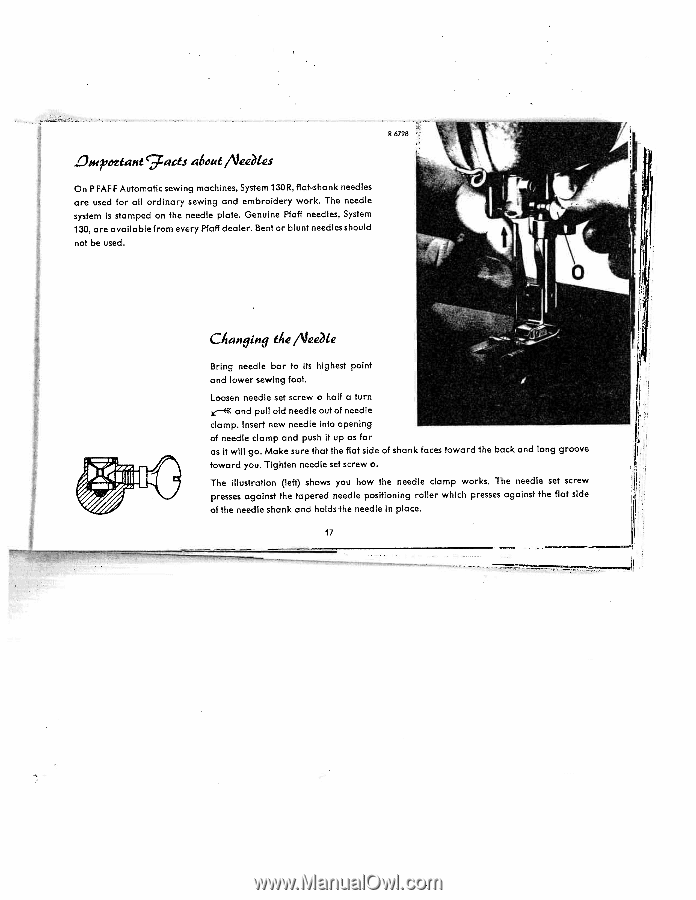

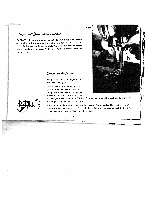

R 6798 Dit,1tant 9acts 4&14t /Ve&2ks On PFAFF Automatic sewing machines, System 130R, flat-shank needles are used for all ordinary sewing and embroidery work. The needle system is stamped on The needle plate. Genuine Pfaff needles, System 130, are available from every Pfoff dealer. Bent or blunt needles should not be used. C 6 aqinq the /Vete Bring needle bar to its highest point and lower sewing foot. Loosen needle set screw o half a turn ,c-'tEC and pull old needle out of needle clomp. Insert new needle into opening of needle clamp and push it up as far as it will go. Make sure that the flat side of shank faces toward the back and long groove toward you. Tighten needle set screw 0. The illustration (left) shows you how the needle clamp works. The needle set screw presses against the tapered needle positioning roller which presses against the flat side of the needle shank and holds the needle in place. 17