Ridgid SSP-1000 Operation Manual - Page 5

Specific Safety Information, Description and Specifications - manual

|

View all Ridgid SSP-1000 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

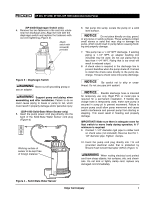

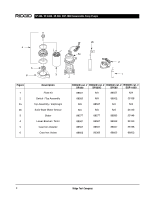

SP-330, SP-330D, SP-500, SSP-1000 Submersible Sump Pumps Service ! WARNING • The motor is oil filled and sealed for cooler running. Allow 2 hours for the motor to cool before servicing. Hot oil is under pressure and could result in severe burns. • Pump service must be performed only by qualified repair personnel. Service or maintenance performed by unqualified repair personnel could result in injury and may void the warranty. • When servicing a pump, use only identical replacement parts. Follow instructions in the Maintenance Section of this manual. Use of unauthorized parts or failure to follow maintenance instructions may create a risk of electrical shock or injury. NOTE! Disassembly of the motor will void warranty. Specific Safety Information ! WARNING Risk of electric shock. This pump is supplied with a grounding-type plug. To reduce risk of electric shock be certain that it is connected only to a properly grounded, grounding-type receptacle that is protected by a GFCI. For your own safety, before assembling and operating this unit, read this operators manual carefully and completely. Learn the operation, application, and potential hazards peculiar to this unit. Call the Ridge Tool Company, Technical Services Department at (800) 519-3456 if you have any questions. Submersible Pump Safety ! DANGER • Do not use to pump flammable or explosive fluids such as gasoline, fuel oil, kerosene, solvents, thinners etc. Do not use in a flammable and/or explosive atmosphere. Pump should only be used to pump clear water. Improper use could result in personal injury and/or death. ! WARNING • If there is water or moisture on the floor or ground near the pump, do not walk on wet area until all power is turned off. If the shut-off box is in the basement, call an electrician. Failure to follow this warning could result in fatal electrical shock. • Always disconnect the power source before attempting to install, service, relocate, or maintain the pump. Never handle a pump or pump motor with wet hands or when standing on wet or damp surface or in water. Failure to follow this warning could result in personal injury and/or death. • Pump motor is equipped with automatic resetting thermal protector that could restart unexpectedly. Disconnect power source when servicing pump. • Do not modify float or position float switch so that pump will operate continuously. Pump is not designed for continuous operation, this will reduce performance and life of the pump. • Do not hang pump by handle for permanent installation. This minimizes twisting which can lead to damage during pump operations. Description and Specifications Description The submersible pump is designed for home sump operations only. The unit is equipped with an 8 foot, 3prong grounding type power cord. The motor has an automatic reset thermal protector to prevent burnouts due to overloading or clogging. The pump is designed to automatically maintain water level between factory preset points. The SSP-1000 is provided with a solid-state electronic water level control. When water is detected, the pump will start automatically. NOTICE This pump is not designed to handle salt water, brine, laundry discharge, or any other application which may contain caustic chemicals and/or foreign materials. This pump is not suitable for use with aquatic life. Pump damage or failure could occur if used in these applications and will void the warranty. NOTICE It is strongly recommended that a battery back-up system be used. Power outages, excessive water flow, G.F.C.I. tripping and primary pump wear can cause flooding. A battery back-up system reduces this risk. Contact your Ridge Tool distributor. Ridge Tool Company 3