Sub-Zero BI-36R Built-In Installation Guide - Page 30

Panel Installation, Flush Inset Panels

|

View all Sub-Zero BI-36R manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 30 highlights

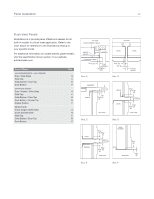

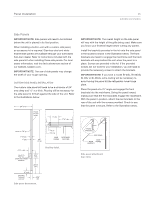

Panel Installation 30 Flush Inset Panels If your customer has chosen the flush inset panel application, make sure that the panels you are about to install match dimensions listed in the flush inset panel specifications on pages 32-33. Additional panel design information can be found in the Sub-Zero design guide and on our website, subzero.com. IMPORTANT NOTE: The size of the flush inset panel is critical. It must be sized correctly for a proper fit inside the opening. Overlay models are shipped without handle hardware. The cabinet manufacturer or designer will provide handle hardware at the job site to match the overall decorating scheme. To install flush inset panels, first remove the door trim molding. For side-by-side models and the upper door for over-and-under models, insert a screwdriver tip into the top corner slot on the handle side and pop out the trim molding. Remove the screws and frame. For the drawer on over-and-under models, insert a screwdriver tip into the slot on either side of the trim molding running along the top of the drawer, and pop out the trim molding. Remove the screws and frame. Refer to the illustrations on page 23. Flush Inset Panel Requirements MAX WEIGHT PER PANEL BI-36R, BI-36RG and BI-36F All Other Flush Inset Models Grille Panel MIN PANEL THICKNESS All Flush Inset Panels 75 lbs (34 kg) 50 lbs (23 kg) 13 lbs (6 kg) 5/8" (16) Sub-Zero allows a 1/4" (6) space to slide the backing material into place in the frame. If your material is thicker than a 1/4" (6), either rout an edge around the panel to get a proper fit or mount the decorative flush inset panel on a sheet of 1/4" (6) thick material and insert the backing material into the channel. You must allow for 0.10" (3) space between the backer board and the decorative panel, so the panel will slide easily into the door frame. The illustration below provides a rear view of the threepanel assembly with critical dimensions, standard for all built-in models. IMPORTANT NOTE: With the panels installed, 1/2" (13) minimum reveals must be kept on all sides to ensure proper door opening and sufficient cooling of the unit. FLUSH INSET PANEL SPACER PANEL BACKER PANEL 3/4" (19) .10" (3) 1/4" (6) typical Three-panel assembly.