Sub-Zero BI-36S Sub-Zero Design Guide - Page 24

Built-In Refrigeration, Flush Inset Panels - bi 36r

|

View all Sub-Zero BI-36S manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 24 highlights

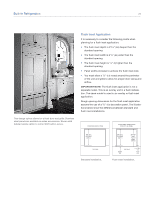

Built-In Refrigeration 24 Flush Inset Panels The flush inset application allows decorative panels on the front of the unit to be flush with surrounding cabinetry and is available for all built-in overlay models. For exact panel dimensions, refer to flush inset panel specifications on the following pages. The flush inset design allows decorative panels to cover the door trim for a seamless appearance that blends with the design of the room. The most common way to achieve this look is to work with three panels-the decorative flush inset panel, which is typically 3/4" (19), a .10" (3) spacer panel and a 1/4" (6) backer panel. Depending on your cabinet manufacturer, this could also be one panel routed for different dimensions. Regardless of the physical construction of the panels (three-panel assembly or routed panel), you will need to follow the flush inset panel specifications on the following pages for exact sizing and panel placement to ensure a proper fit. Do not exceed flush inset panel dimensions, as this could cause damage to panels and the Sub-Zero unit. Flush Inset Panel Requirements MAX WEIGHT PER PANEL BI-36R, BI-36RG and BI-36F All Other Flush Inset Models Grille Panel MIN PANEL THICKNESS All Flush Inset Panels 75 lbs (34 kg) 50 lbs (23 kg) 13 lbs (6 kg) 5/8" (16) The illustration below provides a rear view of the threepanel assembly with critical dimensions, standard for all built-in models. IMPORTANT NOTE: The inside edges of the rough opening as well as the sides and a portion of the back side of the decorative panels will need to be finished, as they will be exposed when the doors are open. IMPORTANT NOTE: On glass door models, the edges of the overlay, spacer and backer panels of the window cut-out will need to be finished, as they will be exposed. IMPORTANT NOTE: For flush inset panels thicker than 3/4" (19), a 90° door stop may be required to prevent interference with adjacent cabinets. Refer to the full-scale templates at the end of this section. IMPORTANT NOTE: When installing two units side by side in a flush inset application, refer to pages 32-36 for dual flush inset installations. Be aware that rough opening dimensions, panel sizes and offsets are different for this application. FLUSH INSET PANEL SPACER PANEL BACKER PANEL 3/4" (19) .10" (3) 1/4" (6) typical Three-panel assembly.