Weider X2 Uk Manual - Page 19

Maintenance and Trouble-shooting

|

View all Weider X2 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

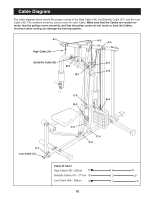

Maintenance and Trouble-shooting Inspect and tighten all parts each time you use the training system. Replace any worn parts immediately. The training system can be cleaned using a damp cloth and mild non-abrasive detergent. Do not use solvents. Tightening the Cables Woven cable, the type of cable used on the training system, can stretch slightly when it is first used. If there is any slack in the cables before resistance is felt, the cables should be tightened. Slack can be removed by moving one or both of the Pulleys (50) attached to the Pulley Plates (25) to different holes in the Pulley Plates. To do this, remove the M10 x 50mm Bolt (54) and the M10 Nylon Locknut (60). Move the Pulley and the Pulley Covers (28) one hole up or down and re-attach them with the Bolt and Nylon Locknut. Make sure that the Low Cable (40) or the High Cable (48) is in the groove of the Pulley. After moving one of the Pulleys (50) one hole up or down, test the training system to see if the cables are tight. If the cables are still loose, move the second Pulley one hole. Repeat this process until the cables are tight. 50 54 28 50 40 48 25 60 28 Additional slack can be removed by adjusting the M8 x 75mm Eyebolt (69) to which the Low Cable (40) is attached. To do this, loosen the M8 Nylon Locknut (70) without removing it. Then, tighten the M8 Plain Nut (70) further onto the Eyebolt. Finally, retighten the M8 Nylon Locknut. 4 40 Note: If a cable tends to slip off the pulleys often, the cable may have become twisted. Remove the cable 69 and re-install it. If the cables need to be replaced, see ORDERING REPLACEMENT PARTS on the back cover of this manual. 71 70 19