Brother International BAS-375E Extended Option Output Instruction Manual - Eng - Page 3

Basic

|

View all Brother International BAS-375E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

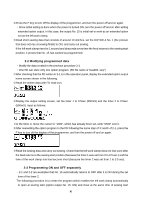

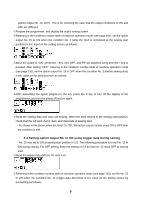

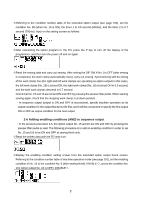

Basic 1. Preparation Sewing machine with the pneumatic work clamp (except for BAS-311E solenoid specification) Control PROM version MN-C or later (products manufactured in or after June 1998 are equipped with this PROM as a standard part.) Programmer Instruction manual for programmer (see the instruction manual for page reference.) 2. Examples of simple option output Option output can be programmed up to No. 16 (see page 195). No. 15 is the air valve output for the left work clamp, and No.16 is the air valve output for the right work clamp. If these two outputs are programmed as option outputs, these do not operate as the work clamps but operate as the option outputs. The following example operations are to program No. 15 and 16 and check their operations (if the right and left work clamps operate as programmed, the operations of No. 15 & 16 are good). Some of the following examples involve sewing operation with the work clamp raised, be extremely careful in that case. 2-1 ON & OFF operation synchronizing with one machine operation Create program that enables the right and left work clamps automatically to rise and descend (option output No. 15 is ON and OFF) at sewing start. •Prepare the programmer, follow "Operating the extended option output" (see page 184) to display the output setting screen. ,Referring to the condition number table of machine operation mode (see page 191), set the option output No. 15 to ON when the condition No. 2 is set, and the timer 2 to 1 second (1000ms). Input on the setting screen as follows: Press the RETURN key to save the data after inputting the numerical data. For input check, move the cursor to OUPTPUT No., set it to No. 16 by pressing the + key once, and set it back to No. 15 by pressing the − key. ƒPress the ESC key, and write the data with the FD write icon. 3