Craftsman 21833 Operation Manual - Page 7

Riving Knife To Blade Adjustment - assembly

|

View all Craftsman 21833 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

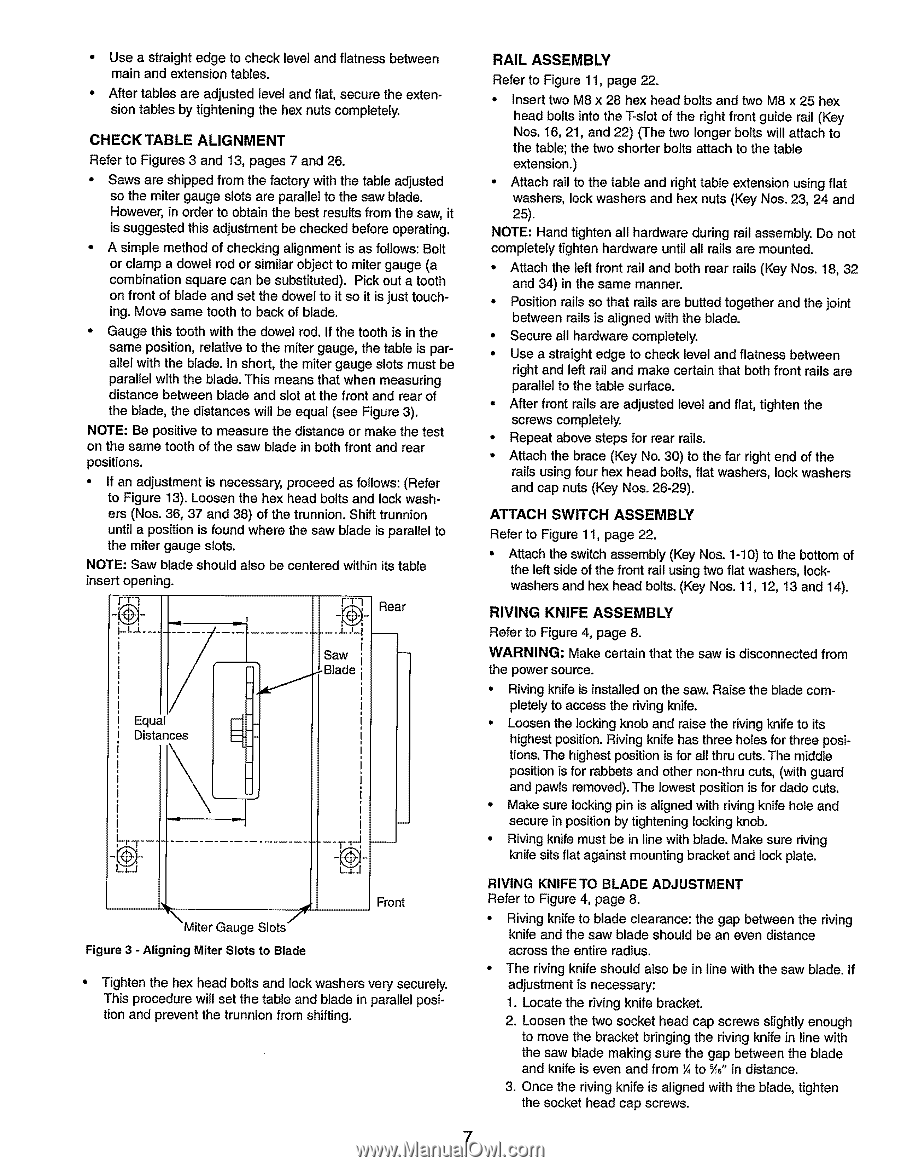

• Use a straight edge to check level and flatness between main and extension tables. • After tables are adjusted level and flat, secure the extension tables by tightening the hex nuts completely. CHECK TABLE ALIGNMENT Refer to Figures 3 and 13, pages 7 and 26. • Saws are shipped from the factory with the table adjusted so the miter gauge slots are parallel to the saw blade. However, in order to obtain the best results from the saw, it is suggested this adjustment be checked before operating. ° A simple method of checking alignment is as follows: Bolt or clamp a dowel rod or similar object to miter gauge (a combination square can be substituted). Pick out a tooth on front of blade and set the dowel to it so it is just touching. Move same tooth to back of blade. • Gauge this tooth with the dowel rod. If the tooth is in the same position, relative to the miter gauge, the table is parallel with the blade. In short, the miter gauge slots must be parallel with the blade. This means that when measuring distance between blade and slot at the front and rear of the blade, the distances will be equal (see Figure 3). NOTE: Be positive to measure the distance or make the test on the same tooth of the saw blade in both front and rear positions. • If an adjustment is necessary, proceed as follows: (Refer to Figure 13). Loosen the hex head bolts and lock washers (Nos. 36, 37 and 38) of the trunnion. Shift trunnion until a position is found where the saw blade is parallel to the miter gauge slots. NOTE: Saw blade should also be centered within its table insert opening. , r_Y Rear __'1",_j, _aw : _Blade : t I 1 I i I i I i I i 1 1 I i I i "'Miter Gauge Slots ''f Figure 3 - Aligning Miter Slots to Blade Front ° Tighten the hex head bolts and lock washers very securely. This procedure will set the table and blade in parallel position and prevent the trunnion from shifting. RAIL ASSEMBLY Refer to Figure 11, page 22. ° Insert two M8 x 28 hex head bolts and two M8 x 25 hex head bolts into the T-slot of the right front guide rail (Key Nos. 16, 21, and 22) (The two longer bolts will attach to the table; the two shorter bolts attach to the table extension.) • Attach rail to the table and right table extension using flat washers, lock washers and hex nuts (Key Nos. 23, 24 and 25). NOTE: Hand tighten all hardware during rail assembly. Do not completely tighten hardware until all rails are mounted. • Attach the left front rail and both rear rails (Key Nos. 18, 32 and 34) in the same manner. • Position rails so that rails are butted together and the joint between rails is aligned with the blade. • Secure all hardware completely. • Use a straight edge to check level and flatness between right and left rail and make certain that both front rails are parallel to the table surface. • After front rails are adjusted level and flat, tighten the screws completely. • Repeat above steps for rear rails. • Attach the brace (Key No. 30) to the far right end of the rails using four hex head bolts, flat washers, lock washers and cap nuts (Key Nos. 26-29). ATTACH SWITCH ASSEMBLY Refer to Figure 11, page 22. • Attach the switch assembly (Key Nos. 1-10) to the bottom of the left side of the front rail using two flat washers, lockwashers and hex head bolts. (Key Nos. 11, 12, 13 and 14). RIVING KNIFE ASSEMBLY Refer to Figure 4, page 8. WARNING: Make certain that the saw is disconnected from the power source. • Riving knife is installed on the saw. Raise the blade completely to access the riving knife. • Loosen the locking knob and raise the riving knife to its highest position. Riving knife has three holes for three positions. The highest position is for all thru cuts. The middle position is for rabbets and other non-thru cuts, (with guard and pawls removed). The lowest position is for dado cuts. • Make sure locking pin is aligned with riving knife hole and secure in position by tightening locking knob. • Riving knife must be in line with blade. Make sure riving knife sits flat against mounting bracket and lock plate. RIVING KNIFE TO BLADE ADJUSTMENT Refer to Figure 4, page 8. • Riving knifeto blade cJearancet:he gap between the riving knife and the saw blade should be an even distance across the entire radius. • The rivingknifeshouldalso be in line with the saw blade, if adjustmentis necessary: 1. Locatethe riving knife bracket. 2. Loosenthe two sockethead cap screws slightlyenough to move the bracketbringing the rivingknife in linewith the saw blade makingsure the gap between the blade and knifeis even and from ¼to _," in distance, 3. Once the riving knife is alignedwiththe blade, tighten the socket head cap screws. 7