Cub Cadet LS 25 CC H Operation Manual - Page 10

Hose Clamps, Hydraulic Filter, Flexible Pump Coupler, Off-Season Storage

|

View all Cub Cadet LS 25 CC H manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 10 highlights

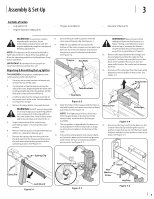

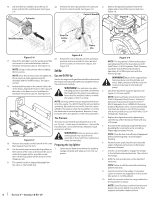

Hose Clamps Check the clamps on the return hose before each use and check the clamps on the suction hose once a season. Hydraulic Filter Change the hydraulic filter every 50 hours of operation. Use only a 10 micron hydraulic filter. Order part number 723-0405. Beam Lubricate both sides of the beam (where it comes into contact with the splitting wedge), before each use, with engine oil. Service Flexible Pump Coupler The flexible pump coupler is a nylon "spider" insert, located between the pump and the engine shaft. Over time, the coupler will harden and deteriorate. Replace the coupler if you detect vibration or noise coming from the area between the engine and the pump. If the coupler fails completely, you will experience a loss of power. NOTE: On vertical shaft engines, it will be necessary to remove the engine to access the hex screws securing the pump to the engine shaft. Taking the log splitter to an authorized service dealer is recommended. NOTE: Never hit the engine shaft in any manner, as a blow will cause permanent damage to the engine. 1. Disconnect the spark plug wire and ground it against the engine. 2. Remove the three flange lock nuts and hex screws that secure the pump to the coupling shield. Two flange lock nuts and hex screws are at the bottom corners and one is in the top center. See Figure 5-5 Hex Screw .090 .020 Set Screw Flange Lock Nut Figure 5-5 3. Remove the pump. 4. Loosen the set screw on the pump coupling half and remove the coupling half. 5. Rotate the engine by slowly pulling the starter handle until the engine coupling half set screw is at the bottom. Loosen the set screw using an allen wrench and slide the coupling half off the engine shaft. 6. Slide the new engine coupling half onto the engine shaft until the end of the shaft is flush with the inner portion of the coupling half. (There must be space between the end of the engine support bracket and the coupling half). Tighten the set screw. 7. Install the nylon "spider" onto the engine coupling half. 8. Install the pump coupling half and key on the pump shaft. Rotate the coupling half until the set screw faces down. Do not tighten set screw. 9. Align the pump coupling half with the nylon "spider" by rotating the engine using the starter handle. Slide the coupling half into place while guiding the three mounting bolts through the holes in the pump support bracket. 10. Secure with the nuts removed earlier. 11. Set .020" to .090" of a clearance/gap between the nylon "spider" and the engine coupling half by sliding a feeler gauge between the nylon "spider" and the engine coupling half and moving the pump coupling half as needed. Install the set screw and torque to 78 in-lbs to secure the pump coupling half. See Figure 5-5. NOTE: Make certain the proper clearance/gap is obtained before tightening the set screw. 12. Reconnect the spark plug. Off-Season Storage If the log splitter will not be used for more than 30 days, prepare it for storage as follows: WARNING! Never store the machine with fuel in the fuel tank inside of building where fumes may reach an open flame or spark, or where ignition sources are present such as hot water and space heaters, furnaces, clothes dryers, stoves, electric motors, etc. 1. Refer to the Engine Operator's manual packed with your log splitter for information on the off-season storage of the engine. 2. Clean the log splitter thoroughly. NOTE: Using a pressure washer or garden house to clean the log splitter is not recommended. They may cause damage to the bearings or the engine. The use of water will result in a shortened life and reduce serviceability. 3. Wipe the machine with an oiled rag to prevent rust, especially on the wedge and the beam. 4. Store the log splitter in a clean, dry area. Do not store it next to corrosive materials, such as fertilizer. NOTE: If storing in an unventilated or metal storage shed, be certain to rustproof the equipment by coating it with a light oil or silicone. 10 Section 5- Service