Dewalt DXCM201 Instruction Manual - Page 17

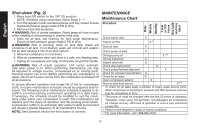

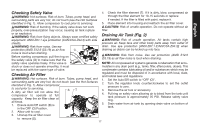

Checking Safety Valve, Checking Air Filter, Draining Air Tank Fig. 2

|

View all Dewalt DXCM201 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

Checking Safety Valve WARNING: Hot surfaces. Risk of burn. Tubes, pump head, and surrounding parts are very hot, do not touch (see the Hot Surfaces 4. Check the filter element (T). If it is dirty, blow compressed air through the filter element for 10-15 seconds or replace if needed. If the filter is filled with paint, replace it. English identified in Fig. 1). Allow compressor to cool prior to servicing. 5. Place element into housing and reattach the air filter cover. WARNING: Risk of bursting. If the safety valve does not work CAUTION: Risk of unsafe operation. Do not operate without air properly, over-pressurization may occur, causing air tank rupture filter. or an explosion. WARNING: Risk from flying objects. Always wear certified safety equipment: ANSI Z87.1 eye protection (CAN/CSA Z94.3) with side shields. WARNING: Risk from noise. Use ear protection (ANSI S12.6 (S3.19) as air flow G Draining Air Tank (Fig. 2) WARNING: Risk of unsafe operation. Air tanks contain high pressure air. Keep face and other body parts away from outlet of drain. Use eye protection [ANSI Z87.1 (CAN/CSA Z94.3)] when draining as debris can be kicked up into face. noise is loud when draining. Before starting compressor, pull the ring on the safety valve (G) to make sure that the WARNING: Risk from noise. Use ear protection (ANSI S12.6 (S3.19) as air flow noise is loud when draining. safety valve operates freely. If the valve is NOTE: All compressed air systems generate condensation that accu- stuck or does not operate smoothly, it must mulates in any drain point (e.g., tanks, filter, aftercoolers, dryers). This be replaced with the same type of valve. condensate contains lubricating oil and/or substances which may be Checking Air Filter WARNING: Hot surfaces. Risk of burn. Tubes, pump head, and surrounding parts are very hot, do not touch (see the Hot Surfaces identified in Fig. 1). Allow compressor to cool prior to servicing. A dirty air filter will not allow the ST compressor to operate at full capacity. Keep the air filter clean at all times. 1. Ensure Auto/Off switch (B) is in the OFF (O) Position. regulated and must be disposed of in accordance with local, state, and federal laws and regulations. 1. Set the Auto/Off switch to "OFF (O)". 2. Turn the regulator knob counterclockwise to set the outlet pressure to zero. 3. Remove the air tool or accessory. 4. Pull ring on safety valve allowing air to bleed from the tank until tank pressure is approximately 20 PSI. Release safety valve ring. 5. Drain water from air tank by opening drain valve on bottom of tank. 2. Allow unit to cool. 3. Unsnap the air filter cover to remove (S). 17