Frigidaire FAFS4272LW Wiring Diagram (All Languages) - Page 5

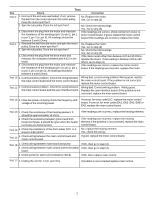

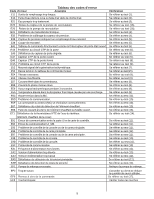

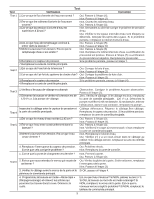

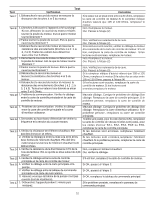

Test 8, Test 9, Test 10, Test 11, Test 12, Test 13, Test 14, Test 15 - motor control

|

UPC - 012505382208

View all Frigidaire FAFS4272LW manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

Test Test Check Correction Test 8: 1. Find out if the unit was overloaded. If not, remove the belt from the motor and spin the motor pulley. Does the motor spin free? No. Replace the motor. Yes. Go to step (2) 2. Spin the tub pulley. Does the tub spin free? No. Check the tub bearings. 3. Disconnect the plug from the motor and measure the resistance of the windings (pin 1 to pin 2, pin 1 to pin 3, pin 2 to pin 3). All readings should be between 3 and 6 Ohms. Yes. Go to step (3) If the readings are correct, check wiring from motor to motor control board, If good, replace the motor control board.If the readings are incorrect, replace the motor. Test 9: 1. Remove the belt from the motor and spin the motor pulley. Does the motor spin free? 2. Spin the tub pulley. Does the tub spin free? No. Replace the motor. Yes. Go to step (2) No. Check the tub bearings. 3. Disconnect the plug from the drive motor and measure the resistance between pins 4 & 5 in the motor. 4. Disconnect the plug from the motor and measure the resistance of the windings (pin 1 to pin 2, pin 1 to pin 3, pin 2 to pin 3). All readings should be Yes. Go to step (3) If the meter reads other than between 105 & 130 Ohms, replace the motor. If the reading is between 105 & 130 Ohms, Go to step (4) If the readings are correct, replace the motor control board. If the readings are incorrect, replace the motor. between 3 and 6 Ohms. Test 10: 1. Communication problem. Check the wiring between Wiring bad, correct wiring problem.Wiring good, replace the main control board and the motor control board. the main control board. If the problem is not corrected, replace the motor control board. Test 11: 1. Communication problem. Check the wiring between Wiring bad. Correct wiring problem. Wiring good. the main control board and the user interface board. Replace the user interface board. If the problem is not corrected, replace the main control board. Test 12: 1. Have the power company check the frequency and voltage of the incoming power. If correct, for error code E5C, replace the motor control board. If correct, for error codes EA1, EA2, EA3, EAE or EA5, replace the main control board Test 13: 1. Check the resistance of the heating element. It should be approximately 14 ohms. 2. Check the resistance between ground and both heater terminals. It should be open when the heater terminals are disconnected. Test 14: 1. Check the resistance of the drum water NTC. Is it around 4.8K ohms? Test 15: 1. Check wiring motor control between board. the main control board and If the readings are incorrect, replace the heating element. If the readings are incorrect, replace the heating element.If the problem is not corrected, replace the main control board. No, replace the heating element. Yes, check the wiring. If good, replace the motor control board. Test 16: 1. Check wiring between main board and pump If OK, then go to step (2). 2. Check wiring between main control and recirculation If OK, then go to step (3). board. 3. Check pump for open coil (resistance check). If OK, then replace main control. Test 17: 1. Unplug the unit for 1 min. and retry. If problem is not corrected replace main control. 5