GE SG50T12TVT Use and Care Manual - Page 19

During Installation of this water heater, Heat Traps - energy rating

|

View all GE SG50T12TVT manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

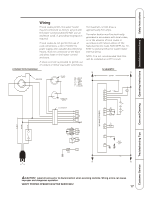

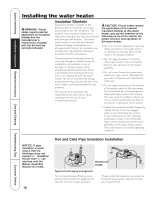

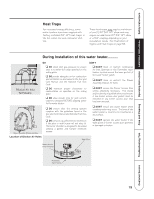

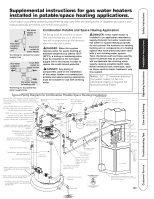

Operating Instructions Installation Instructions Safety Instructions Heat Traps For increased energy efficiency, some water heaters have been supplied with factory installed 3/4" NPT heat traps in the hot outlet line and cold water inlet line. These heat traps may require a minimum of one (1) 90° 3/4" NPT elbow and may require an additional 90° 3/4" NPT elbow or a 3/4" coupling depending on your installation needs. See Illustration of nipples and heat traps on page 33. During Installation of this water heater........... DO DON'T Dilution Air Inlet Tall Models Blower Assembly Dilution Air Holes ❑ DO check inlet gas pressure to ensure that it is within the range specified on the rating plate. ❑ DO provide adequate air for combustion and ventilation as discussed in the Use and Care Manual and the National Fuel Gas Code. ❑ DO maintain proper clearances to combustibles as specified on the rating plate. ❑ DO allow enough time for joint cement vapors to dissipate BEFORE applying power to the water heater. ❑ DO ensure that the venting system complies with the guidelines found in the Use and Care Manual and National Fuel Gas Code. ❑ DO contact a qualified service technician if the pilot or main burner will not stay lit. The burner chamber is designed to be sealed utilizing a gasket and tamper resistant screws. ❑ DON'T block or restrict Combustion Air Inlet Openings or the Flammable Vapor Sensor located around the lower portion of the water heater jacket. ❑ DON'T block or restrict the Blower Assembly Dilution Air holes. ❑ DON'T remove the Burner Access Door unless absolutely necessary. This should only be done by a qualified service technician. A new burner access door gasket must be installed on any burner access door that has been removed. ❑ DON'T install this water heater where standing water may occur. The base of the water heater is meant to be mounted on a dry surface. ❑ DON'T operate the water heater if the sight glass or burner access door grommet is damaged or broken. Location of Dilution Air Holes Sight Glass Burner Access Door Grommet Flammable Vapor Sensor Care and Cleaning Troubleshooting Tips Customer Service 19