HP Scitex LX600 HP Scitex LX Printer Family - Site preparation guide - Page 15

Ventilation and air conditioning, Printing on porous substrates—visible vapor, Load bearing - latex printer

|

View all HP Scitex LX600 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 15 highlights

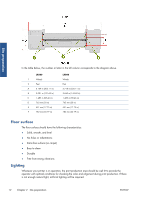

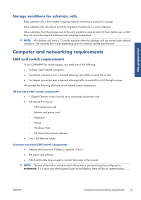

Site preparation Ventilation and air conditioning As with all equipment installations, to maintain ambient comfort levels, air conditioning or ventilation in the work area should take into account that the printer produces heat. Specifically, the LX600 printer's power dissipation is 12 KW (41 KBTU/h), and the LX800 printer's power dissipation is 15 KW (51 KBTU/h). Air conditioning and ventilation should meet with local environmental, health and safety (EHS) guidelines and regulations. Consult your usual air conditioning or EHS specialist for advice on the appropriate measures for your location. For a more prescriptive approach to adequate ventilation, you could refer to the ANSI/ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers) 62.1-2007 Ventilation for Acceptable Indoor Air Quality. As an example, a minimum exhaust rate of 2.5 L/s.m² (0.5 cfm/ft²) of fresh make up air for "copy, printing rooms" is specified. NOTE: The ventilation and air conditioning units should not blow air directly onto the printer. NOTE: You are recommended to maintain a positive airflow in the print production room to help prevent dust from entering the room. Printing on porous substrates-visible vapor Under some conditions of ambient temperature and relative humidity, visible vapors may be produced when printing with water-based HP Latex inks, especially when printing on porous substrates. In high-production environments, it is recommended that supplementary ventilation be considered to maintain comfort levels and prevent condensation, especially when printing in a confined area on porous substrates. Special ventilation is not required to meet US OSHA requirements on occupational exposure to VOCs from HP Latex inks. Special ventilation-equipment installation is at the discretion of the customer-no specific HP recommendation is intended for special ventilation. Customers should consult state and local requirements and regulations. Load bearing The load-bearing characteristics of the floor in the print production area must be sufficient to withstand the weight of your printer. To calculate the load bearing characteristics of the print production floor, you must consult a structural engineer. Printer weight without substrate Load on each foot LX600 981 kg (2163 lb) 327 kg (721 lb) LX800 1100 kg (2425 lb) 367 kg (809 lb) Your printer has four wheels used to move the printer and three feet that must be lowered to touch the ground and support the printer. The following diagram shows where the feet and wheels touch the ground, in case you need extra reinforcements. ENWW Room and spacial requirements 11