Honeywell HW7500E Service Manual - Page 31

Valve Lash, Governor Adjustment - specifications

|

UPC - 894190002049

View all Honeywell HW7500E manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 31 highlights

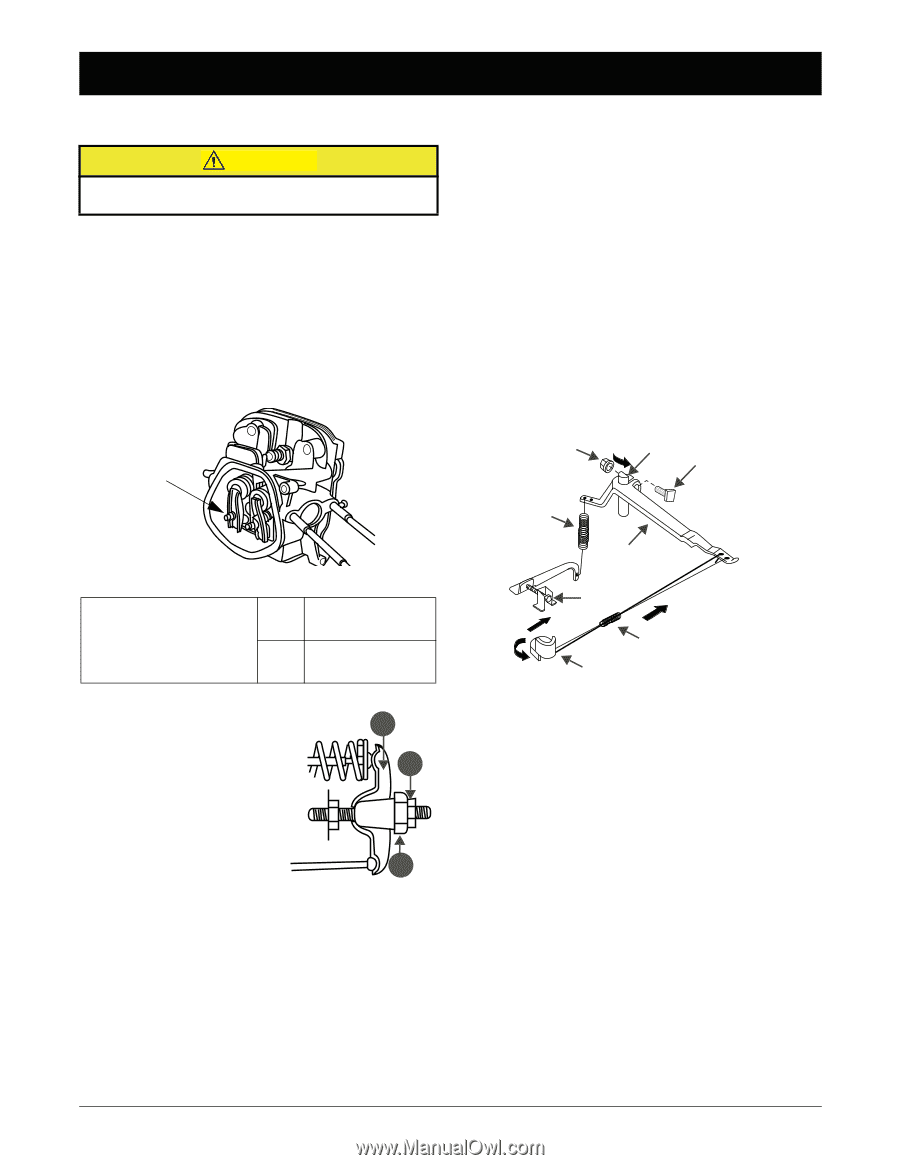

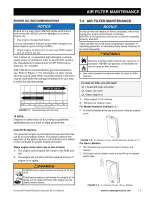

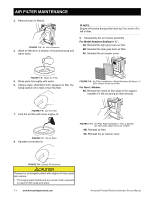

VALVE LASH 7.6 VALVE LASH CAUTION Valve lash inspection and adjustment must be performed with the engine cold. 1. Remove the cylinder head cover and carefully remove the gasket for re-use. (Inspect and replace gasket, if necessary.) 2. Remove the spark plug to reduce engine compression resistance. 3. Turn the engine crankshaft using the recoil starter, positioning engine at top, dead center, of the compression stroke. This can be verified by the piston position in the cylinder. 4. Insert a feeler gauge between the rocker arm and valve spring to measure valve lash. 7.7 GOVERNOR ADJUSTMENT 1. Start the engine and run with no load. 2. Attach a frequency meter and adjust the limiting screw on the governor stop to 62.5 Hz ± 0.5. 3. Stop the engine. 4. If frequency is out of range, see the "GOVERNOR RANGE ADJUSTMENT" procedure below. 5. Repeat steps 1 through 3. If frequency still out of range, see ENGINE DIAGNOSTICS (ALL MODELS), page 8-10 7.8 GOVERNOR RANGE ADJUSTMENT 1. Remove the generator control panel for access. 2. Loosen the nut on the governor arm pinch bolt (see illustration). LOCK NUT NUT GOVERNOR SPRING GOVERNOR ARM SHAFT GOVERNOR ARM PINCH BOLT FIGURE 7-17: Lock Nut Location IN. Standard valve lash EX. TABLE 7-5. Standard Valve Lash A-ROCKER ARM B-LOCK NUT 12 N•m (9 lb. ft.) • To increase valve lash, screw pivot nut out. • To decrease valve lash, screw pivot nut in. C-PIVOT BOLT 30 N•m (22 lb. ft.) 0.005±0.001 in (0.125±0.025 mm) 0.007±0.001 in (0.175±0.025 mm) A B C GOVERNOR ARM LIMITING SCREW ANTI-SURGE SPRING THROTTLE FIGURE 7-18: Governor Arm Assembly 3. Rotate the governor arm shaft counter-clockwise until the throttle is completely open and hold in position. 4. Tighten the nut on the governor arm pinch bolt to maintain position. 5. Confirm the governor arm and throttle move smoothly and do not bind. 6. Reinstall the generator control panel. 5. Hold the rocker arm pivot and loosen the lock nut (see B in illustration). 6. Turn the rocker arm pivot (see C in illustration) to obtain specified valve lash. 7. Retighten the lock nut while holding rocker arm pivot and torque to 12 N•m (9 lb. ft.). 8. Check valve lash again after tightening lock nut. 9. Repeat steps 4 through 7, as needed, until valve lash is within specifications. 10. Reassemble the spark plug, cylinder head cover, and gasket. Honeywell Portable Electrical Generator Service Manual www.honeywellgenerators.com 7-7