Maytag MEDE900VJ Installation Instructions - Page 11

Rventing - review

|

UPC - 883049144764

View all Maytag MEDE900VJ manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

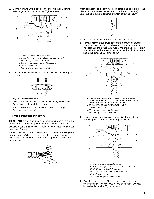

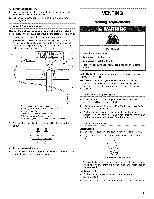

4. Tighten strain relief screw. 5. Insert tab of terminal block cover into slot of dryer rear panel. Secure cover with hold-down screw. 6. You have completed your electrical connection. Now go to "Venting Requirements." Optional 3-wire connection Use for direct wire or power supply cord where local codes do not permit connecting cabinet-ground conductor to neutral wire. 1. Remove center, silver-colored terminal block screw. 2. Remove neutral ground wire from external ground conductor screw. Connect neutral ground wire and the neutral wire (white or center wire) of power supply cord/cable under center, silvercolored terminal block screw. Tighten screw. VENTING Venting Requirements Fire Hazard Use a heavy metaN vent. Do not use a plastic vent. Do not use a metal foil vent. Failure to follow these instructions can result in death or fire. F A. External ground conductor screw B. Center, silver-colored terminal block screw C. Neutral ground wire D. Neutral wire (white or center wire) E. 3/4"(19 mm) UL listed strain relief E Grounding path determined by a qualified electrician 3, Connect the other wires to outer terminal block screws. Tighten screws. !!! ii R ii WARNING: To reduce the risk of fire, this dryer MUST BE EXHAUSTED OUTDOORS. IMPORTANT: Observe all governing codes and ordinances. The dryer exhaust must not be connected into any gas vent, chimney, wall, ceiling, attic, crawlspace, or a concealed space of a building. If using an existing vent system • Clean lint from the entire length of the system and make sure exhaust hood is not plugged with lint. • Replace any plastic or metal foil vent with rigid heavy metal vent or flexible metal vent. Review vent system chart. Modify existing vent system if necessary to achieve the best drying performance. Only rigid or flexible metal vent shall be used for exhausting. If this is a new vent system Vent material • Use a heaw metal vent. Do not use plastic or metal foil vent. • 4" (102 mm) heavy metal exhaust vent and clamps must be used. 4, Tighten strain relief screws. 5. Connect a separate copper ground wire from the external ground conductor screw to an adequate ground. 4" (102 mm) heavymetalexhaust vent Vent products can be purchased from your dealer or by calling Whirlpool Service. For more information, see the "Assistance or Service" section. Rigid metal vent • For best drying performance, rigid metal vents are recommended. • Rigid metal vent is recommended to avoid crushing and kinking. 11