Poulan 4400-4900-5400 User Manual - Page 11

CARBURETOR, ADJUSTMENT, Model, Speed, Mixture, Screw, Ictle, FILTER, MOUNTS

|

View all Poulan 4400-4900-5400 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

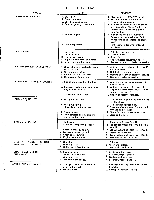

CARBURETOR ADJUSTMENT (Model 4400/4900/5400) STOP THE ENGINE - Make sure you are using clean, fresh fuel mixture at the correct gasoline/oil ratio. THE AIR FILTER MUST BE CLEAN AND FASTENED SECURELY. The cylinder shield should be in place and fastened securely. 1. Turn the high speed and low speed mixture screws clockwise ono* until they stop. DO NOT TIGHTEN OR FORCE THE SCREWS ANY FARTHER! YOU MAY DAMAGE THE NEEDLE SEATS. Turn the high speed and low speed mixture screws 1 full turn counterclockwise. /raft Figure 19. CAUTION! THE CHAIN WILL BE MOVING DURING THE FOLLOWING PROCEDURE. 2. Start the engine and run for a few minutes to bring it to operating temperature. 3. Squeeze the throttle trigger and run the engine at full RPM for approximately 3 SECONDS, then allow it to return to idle speed. 4. If the engine will not idle after it is warm, or it idles too fast causing the chain to move, adjust the idle speed screw. Turn the screw clockwise sow* to increase idle speed, counterclockwise Aran* to decrease idle speed. The idle speed should be set as fast as possible, without causing the chain to move. 5. Turn the low speed mixture screw clockwise until the engine RPM increases and then starts to decrease. Note this setting point. Now turn the screw counterclockwise 4-gif until the RPM starts to decrease again. Set the low speed mixture screw midway between these two points. 6. Squeeze the throttle trigger quickly. If the engine dies or hesitates, turn the low speed mixture screw 1/16 turn counterclockwise tole . Repeat this procedure until the engine will accelerate without hesitation. CAUTION! THE HIGH SPEED MIXTURE SCREW MUST NEVER BE SET AT LESS THAN 7/8 TURN OPEN. A. LEAN MIXTURE WILL CAUSE THE ENGINE TO RUN HOT AND DAMAGE IT. 7. With the high speed mixture screw 1 full turn open, make a test cut with the saw. If the engine fails to have power and run smoothly during the test cut, allow the engine to return to idle speed, and turn the high speed mixture screw 1/16 turn clockwise rm.*. Make another test cut. Continue this procedure until the engine runs smoothly and with power in the test cut. REMINDER -NEVER SET THE HIGH SPEED MIXTURE SCREW LESS THAN 7/8 TURN OPEN. 8. After the low speed and high speed mixture settings are made, it may be necessary to re-adjust the engine idle speed. Refer to step 4. AIR FILTER Clean the air filter after every 10 tanks of gas or every 5 hours of operation. TO CLEAN: 1. Close choke to prevent dirt from entering carburetor. 2. Remove the cylinder cover, then remove air filter. Fig. 20. 3. Separate the two air filter halves. 4. Using a soft bristled brush such as a small paint brush, brush away all dust or other debris from the filter. 5. Clean by soaking in a non-oily, non-flammable solvent. 6. Allow to dry. 7. Before replacing filter clean away chips, saw dust, and other debris on surfaces filter is to be placed on. WARNING: Do not operate your saw without the air filter in place. Dirt and dust in the air can be drawn in carburetor causing damage to the engine. N._ Figure 20 MOUNTS: Your saw is equipped with a counter-vibe system which consists of 6 isolator mounts Fig. 21. Just as the shock absorbers on a car protect you from jolts and bumps the isolators protect the user from engine, bar and chain vibration. Mounts should be checked daily when saw is in operation and should be replaced when vibration appears • excessive or when mounts develop an out of round or swollen shape. This is usually caused from being exposed to gasoline and oil for long periods of time. IT IS NECESSARY TO REPLACE ALL MOUNTS WHEN A MOUNT FAILURE OCCURS. 4-s 1 High Speed Mixture Screw tv2,34/ i, €4, Ictle Speed Screw / Low Speed Mixture Screw Figure 19 a Figure 21 11