Poulan 4400-4900-5400 User Manual - Page 12

cross-

|

View all Poulan 4400-4900-5400 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

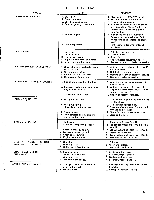

STARTER ROPE If your starter rope breaks near the pulley, it can be repaired by the following method, otherwise replace the rope: 1. Remove the fan housing. 2. Remove screw using a 3/16 alien wrench. Figure 22. 3. Lift out pulley. 4. Tie a knot in one end of the rope. Heat and flatten the knot end to prevent knot from slipping. Heat opposite end of rope and form a point. Feed pointed end of rope through the pulley and under the pulley bridge. Pull the rope through until the knot is tight against the pulley. Figure 22. 5. Pass the pointed end of the rope through the hole in the fan housing and then the starter handle. Tie a double knot and insert knot end of rope back into the handle. Pull the slack out of the rope and wrap the rope on the pulley in a clockwise eism* direction. 6_ Apply light grade silicone lubricant to the pulley bore and place pulley back in the fan housing. Place the pulley washer in position and secure with the pulley screw. 7. To retension the starter spring pull a loop of rope from the pulley approximately 12 in. long. Secure the rope in the notch in the pulley and using the rope turn the pulley THREE TURNS counterclockwise k . Release the rope from the notch and allow to rewind slowly on pulley. Figure 23. 8. Replace the fan housing. GUIDE BAR MAINTENANCE Check the condition of the guide bar often. A worn bar will damage the chain and make cutting harder. 1. Figure 24 shows a cross-section of the guide bar. Keep the edges square as in (1) with a flat file. 2. Rollover is shown in (2). This will cause you to press extra hard when cutting. 3. Worn rails are shown in (3). This occurs most often at the guide bar nos . 4. Uneven rails are shown in (4). This will cause the saw to cut on an angle. 5. Keep the rails flat and square as shown in (1). 6. Grease S/N Bar before use and at least 3 times per day for heavy use. CHAIN SHARPENING Keep Your Chain Sharp Dirt will dull a chain instantly. Keep the chain out of the dirt. If the chain cuts to one side, it is dull. Extra rough cutting is a sign of a dull chain. Powder-l ike wood chips mean a dull chain. Cutting is much easier and safer with a sharp chain. To Sharpen 1. Set the chain tension tight. You must still be able to move the chain around the bar. 2. Clamp the guide bar in a vise. Don't clamp the chain! Clamp in the center of the bar. 3. Use only a 7/32" round file. 4. Sharpen all the cutters away from you first. Then turn the saw around and sharpen the cutters on the other side. 5. Poscition file holder at 10° angle (Figure 25) and align the 30. file holder marks with the bar as shown in Figure 26. 6. File in ONE direction only! Figure 27. 7. Press hard! Two or three strokes should do it. 8. Always check the depth gauge with the depth gauge filing guide after filing. If the depth gauge sticks out, file it off with a flat file, Figure 28. 12 BRIDGE FLATTEN KNOT [FEED ROPE I,. -_, 0-- -.:. r V rti7, -Figure 22 0 - - - 1 Correct Rail & Groove J 2 Rollover _,f( 3 Worn Rails 4 Uneven Rails Figure 24 \ /I* v\ \ N.' ' -::;. 144 Align The File Holder Figure 26 Figure 23 44 10 Figure 25 .,, if 41 File In One Direction Only Figure 27 Depth Gauge / ......, vfr 0, 0 Always Check Depth Gauges Figure 28