Troy-Bilt TB675 Operation Manual - Page 13

Maintenance

|

View all Troy-Bilt TB675 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

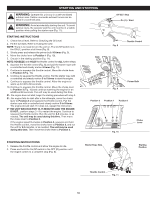

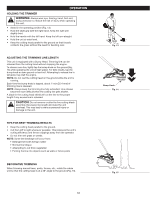

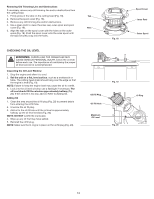

MAINTENANCE WARNING: To prevent serious injury, never perform maintenance or repairs while the unit is running. Always allow the unit to cool before servicing or repairing the unit. Disconnect the spark plug wire to prevent the unit from starting accidentally. MAINTENANCE SCHEDULE Perform these required maintenance procedures at the frequency stated in the table. These procedures should also be a part of any seasonal tune-up. NOTE: Some maintenance procedures may require special tools or skills. If you are unsure about these procedures, take the unit to an MTD authorized service dealer. NOTE: Maintenance, replacement, or repair of the emission control devices and system may be performed by an MTD authorized service dealer. NOTE: Please read the California/EPA statement that came with the unit for a complete listing of terms and coverage for the emissions control devices, such as the spark arrestor, muffler, carburetor, etc. FREQUENCY Every 10 hours After the first 10 hours and at 38 hours MAINTENANCE REQUIRED • Clean and re-oil the air filter. Refer to Maintaining the Air Filter. • Change the oil. Refer to Changing the Oil. • Have the rocker arm clearance checked by an authorized service dealer. • Check the spark plug condition and gap. Refer to Maintaining the Spark Plug. REPLACING THE TRIMMING LINE Only use the trimming line described in the Specifications section. Other types of trimming line may cause the engine to overheat or fail. WARNING: Never use metal-reinforced line, wire, chain or rope. These can break off and become dangerous projectiles. NOTE: Always use the correct line length when installing trimming line. The line may not release properly if the line is too long. NOTE: The outer spool will remain attached to the unit. Installing New Trimming Line 1. If necessary, remove any old trimming line and/or obstructions from the cutting head. Refer to Removing Old Trimming Line and Obstructions. 2. Cut one 20 foot (6 m) length of new trimming line. 3. Turn the bump knob counterclockwise to align the arrows (Fig. 16). 4. Insert the new trimming line into the entry eyelet (Fig. 16). Push the line through the cutting head until a few inches protrude from the exit eyelet. Pull the line until the ends are of equal length. 5. Turn the bump knob counterclockwise to wind the line until about 5 inches (12.7 cm) protrude from each side of the cutting head (Fig. 17). DO NOT push the bump knob down while winding the line. DO NOT align the arrows when the line winding is complete. Entry Eyelet Trimming Line 13 Bump Knob Exit Eyelet Fig. 16 Arrows Fig. 17