Whirlpool CEM2750KQ Installation Instructions - Page 3

To change to a, or 60-minute, timingcam, Exhaust, requirements - dryer parts

|

View all Whirlpool CEM2750KQ manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

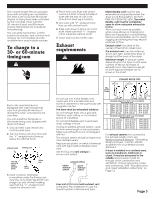

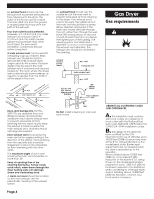

The console houses the accumulator timer with actuating arm and button. The timer is set to provide 45 minutes (4 pins) of drying time when activated by the coin slide. Timer cams for 30- minute (6 pins) and 60-minute (3 pins) drying times are included in the parts bag. The coin-slide mechanism, control panel lock and key, and coin-box lock and key are not included and are available from usual industry sources. To change to a 30- or 60-minute timing cam WARNING Electrical Shock Hazard Disconnect power before making cam changes. Failure to do so can result in death or electrical shock. Each coin-operated dryer is equipped with a 45-minute timer cam that provides 45 minutes of drying time when activated by the coin slide. You can install the 30-minute or 60-minute timing cam (shipped with dryer) as follows: 1. Unlock meter case. Reach into control panel area. 2. Turn the timing cam by hand until the "V" -shaped notch lines up below the ratchet tooth. ratchet tooth timing cam Line up notch to clear ratchet tooth. hub down drive lug 3. Insert a narrow, flat-blade screwdriver under the timing cam near the clock shaft. Gently lift cam straight up and off shaft making sure that the "V" -shaped notch clears the ratchet tooth. 4. Place new cam (hub side down) over clock shaft. Line up flat side of shaft with flat side of cam hole. Check that drive lug is in place. 5. Turn cam until "V" -shaped notch lines up with ratchet tooth. 6. Press cam down in place on motor shaft. Make sure that "V" -shaped notch clears the ratchet tooth. 7. Close and lock the meter case. Exhaust requirements WARNING Fire Hazard Use a heavy metal vent. Do not use a plastic vent. Do not use a metal foil vent. Failure to do so can result in death or fire. Do not use non-metal flexible vent, metal vent that is smaller than four inches in diameter or exhaust hoods with magnetic latches. The dryer must be exhausted outdoors. Do not exhaust dryer into a gas vent, chimney, wall, ceiling, or concealed space of a building. Do not install flexible vent in enclosed walls, ceilings or floors. If using an existing exhaust system, clean lint from entire length of exhaust system. Make sure exhaust hood is not plugged with lint. The exhaust system should be inspected and cleaned yearly. Replace any plastic or metal foil exhaust vent with rigid metal or flexible metal vent. Use 4" (10.2 cm) vent clamps to secure vent system. exhaust airflow better exhaust airflow good exhaust airflow Metal flexible vent must be fully extended and supported when the dryer is in its final position. DO NOT KINK OR CRUSH THE VENT. The metal flexible vent must be completely open to allow adequate exhaust air to flow. Allow as much room as possible when using elbows or making turns. Bend vent gradually to avoid kinking. Remove excess flexible vent to avoid sagging and kinking that may result in reduced air flow. Exhaust outlet is located at the center of the bottom dryer back. The exhaust vent can be routed up, down, left, right, behind the dryer or straight out the back of the dryer. Maximum length of exhaust system depends upon the type of vent used, number of elbows and type of exhaust hood. The maximum length for both rigid and flexible vent is shown in the chart. EXHAUST HOOD TYPE 4" (10.2 cm) 4" (10.2 cm) No. of 90° turns 4" (10.2 cm) 4" (10.2 cm) 4" (10.2 cm) 2-1/2" (6.4 cm) MAXIMUM LENGTH OF 4-INCH (10.2 cm) DIAMETER RIGID METAL VENT 0 64 FT. (19.5 m) 64 FT. (19.5 m) 58 FT. (17.7 m) 1 54 FT. (16.5 m) 54 FT. (16.5 m) 48 FT. (14.6 m) 2 44 FT. (13.4 m) 44 FT. (13.4 m) 38 FT. (11.6 m) 3 35 FT. (10.7 m) 35 FT. (10.7 m) 29 FT. (8.8 m) 4 27 FT. (8.2 m) 27 FT. (8.2 m) 21 FT. (6.4 m) MAXIMUM LENGTH OF 4-INCH (10.2 cm) DIAMETER FLEXIBLE METAL VENT 0 36 FT. (11.0 m) 36 FT. (11.0 m) 28 FT. (8.5 m) 1 31 FT. (9.4 m) 31 FT. (9.4 m) 23 FT. (7.0 m) 2 27 FT. (8.2 m) 27 FT. (8.2 m) 19 FT. (5.8 m) 3 25 FT. (7.6 m) 25 FT. (7.6 m) 17 FT. (5.2 m) 4 23 FT. (7.0 m) 23 FT. (7.0 m) 15 FT. (4.6 m) For exhaust systems not covered by the exhaust length chart, see Whirlpool Service Manual, "Exhausting Whirlpool Dryers," Part No. 603197, available from your Whirlpool parts distributor. If dryer is installed in a confined area, such as a bedroom, bathroom or closet, it must be exhausted to the outside and provision made for enough air for combustion and ventilation. (Check governing codes and ordinances.) See "Recessed area and closet installation instructions" on Page 12. Four-inch (10.2 cm) metal exhaust vent is required. Plan installation to use the fewest number of elbows and turns. Page 3