Whirlpool CEM2750KQ Installation Instructions - Page 5

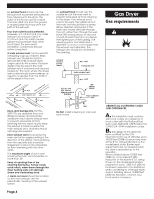

Electrical, requirements, Recommended, ground method

|

View all Whirlpool CEM2750KQ manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

C. Check that dryer is equipped with the correct burner for the particular type of gas used. Burner information can be found on the serial/rating plate in the door well of the appliance. If this information does not agree with the type of gas available, see your dealer. D. This dryer is equipped for use with NATURAL GAS. It is certified by CSA International for manufactured, mixed and L.P. (propane and butane) gases with appropriate conversion. No attempt shall be made to convert the appliance from the gas specified on the serial/rating plate for use with a different gas without consulting the serving gas supplier. Conversion must be done by a qualified service technician. Gas conversion kit part numbers are listed on the gas valve burner base. E. Provide a rigid gas supply line of 1/2-inch IPS pipe to the dryer location. If the total length of the supply line is more than 20 feet (6.1 m), larger pipe will be needed. For L.P. gas usage, 3/8-inch, approved copper tubing may be used. Pipe-joint compounds suitable for use with L.P. gas should be use shutoff valve "open" position to dryer gas supply line F. The supply line shall be equipped with a shutoff valve installed within 6 ft. (1.8 m) of dryer in accordance with the National Fuel Gas Code, ANSI Z223.1 - latest edition*. In Canada, an individual manual shutoff valve must be installed in accordance with the B149 installation codes CAN/CGA B149.1 and CAN/CGA B149.2*. This valve should be located in the same room as the dryer and should be in a location that allows ease of opening and closing. Do Not block access to the shutoff valve. G. If the dryer is installed in a confined area such as a bathroom or closet, provision must be made for enough air for combustion and ventilation. (Check governing codes and ordinances. or refer to the section of this instruction covering recessed and closet installations.) H. If local codes and ordinances permit, it is recommended that new flexible metal tubing, design-certified by the AGA or CSA, be used for connecting the dryer to the gas supply line. (The gas feed pipe which extends through the lower rear of the dryer is provided with 3/8-inch metal pipe thread.) I. If rigid pipe is used as a gas supply line, a combination of pipe fittings must be used to obtain an in-line connection to the dryer. J. Make sure that lower edges of the cabinet, plus the back and bottom sides of the dryer are free of obstructions to permit adequate clearance of air openings for combustion air. See "Recessed area and closet installation instructions," page 12, for minimum spacing requirements. K. For ease of installation, operation and servicing (if ever needed) adequate space should be provided around the dryer. L. A 1/8-inch NPT plugged tapping, accessible for gauge testing, must be installed immediately upstream of the gas supply connection to the dryer. The dryer must be disconnected from the gas supply piping system during any pressure testing of the system at test pressures in excess of 1/2 psig. The dryer must be isolated from the gas supply piping system by closing the equipment shut-off valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3,45 kPa) Electrical requirements WARNING Electrical Shock Hazard Plug into a grounded 3-prong outlet. Do not remove ground prong. Do not use an adapter. Do not use an extension cord. Failure to follow these instructions can result in death, fire, or electrical shock. Important: Observe all governing codes and ordinances. A 120-volt, 60-Hz, AC-only, 15- or 20-ampere fused electrical supply is required. A time-delay fuse or circuit breaker is recommended. It is recommended that a separate circuit serving only this appliance be provided. If codes permit and a separate ground wire is used, it is recommended that a qualified electrician determine that the ground path is adequate. Recommended ground method The dryer, when installed, must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70**, or the Canadian Electrical Code, CSA C22.1*. GROUNDING INSTRUCTIONS: This appliance must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path of least resistance for electric current. The power supply cord plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances. WARNING - Improper connection of the equipment-grounding conductor can result in a risk of electric shock. Check with a qualified electrician or serviceman if you are in doubt as to whether the appliance is properly grounded. Do not modify the plug provided with the appliance - if it will not fit the outlet, have a proper outlet installed by a qualified electrician. 3-prong ground-type outlet 3-prong ground plug power supply cord ground prong Copies of the standards listed above may be obtained from: * CSA International 8501 East Pleasant Valley Road Cleveland, Ohio 44131-5575 ** National Fire Protection Association One Batterymarch Park Quincey, Massachusetts 02269 Page 5