Bernina 1260 Manual - Page 19

Fabric, height, compensation

|

View all Bernina 1260 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 19 highlights

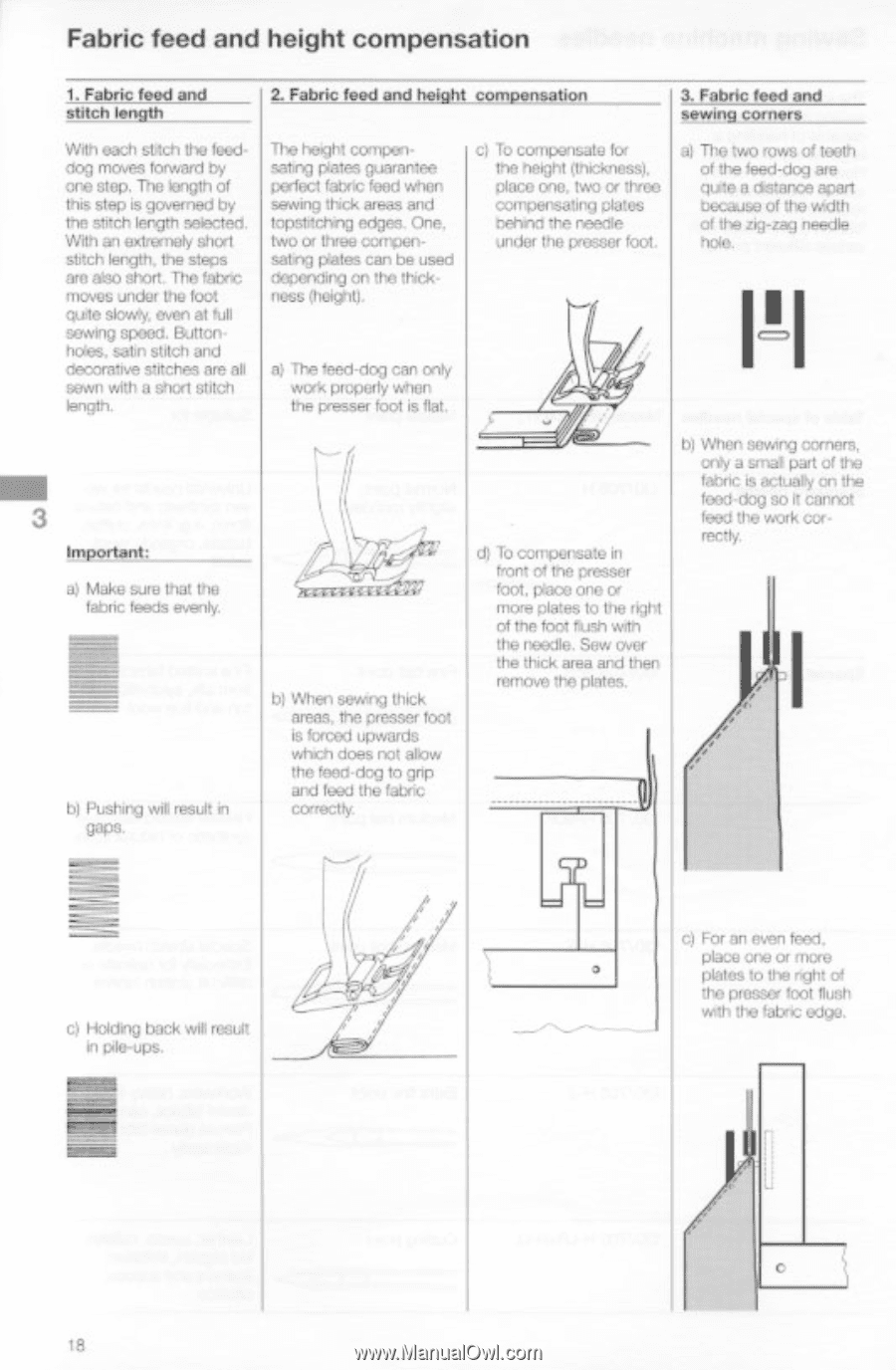

Fabric feed and height compensation 1. Fabric feed and stitch length 2. Fabric feed and height compensation 3. Fabric feed and sowing corners Wrlh each SIAM OW let& clog mpvea toward by one MO The length of this step is governed by trio stitch length SefeCted With an extremely shed stitch length, the steps are also short The fabric moves under Lle loot Cote Slow), oven al full sewing spew. Bunn noise. Sala, stitch and decorative stitches are all sewn with a shed stitch length. height compensating pates geerantee perfect fabric feed whoa sewing thick areas and topstdchng edges. One. Iwo or three (=pen. satag pates can be used depending on the thick floss (lleightt a) The feed.clog can on/y week properly when the presser loot is hat. el To compensate la MO height ghtekness), place en0. two er tivoo compensating c/ateS t>