Bernina 1260 Manual - Page 46

Trouble, shooting, reittystlielglog

|

View all Bernina 1260 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 46 highlights

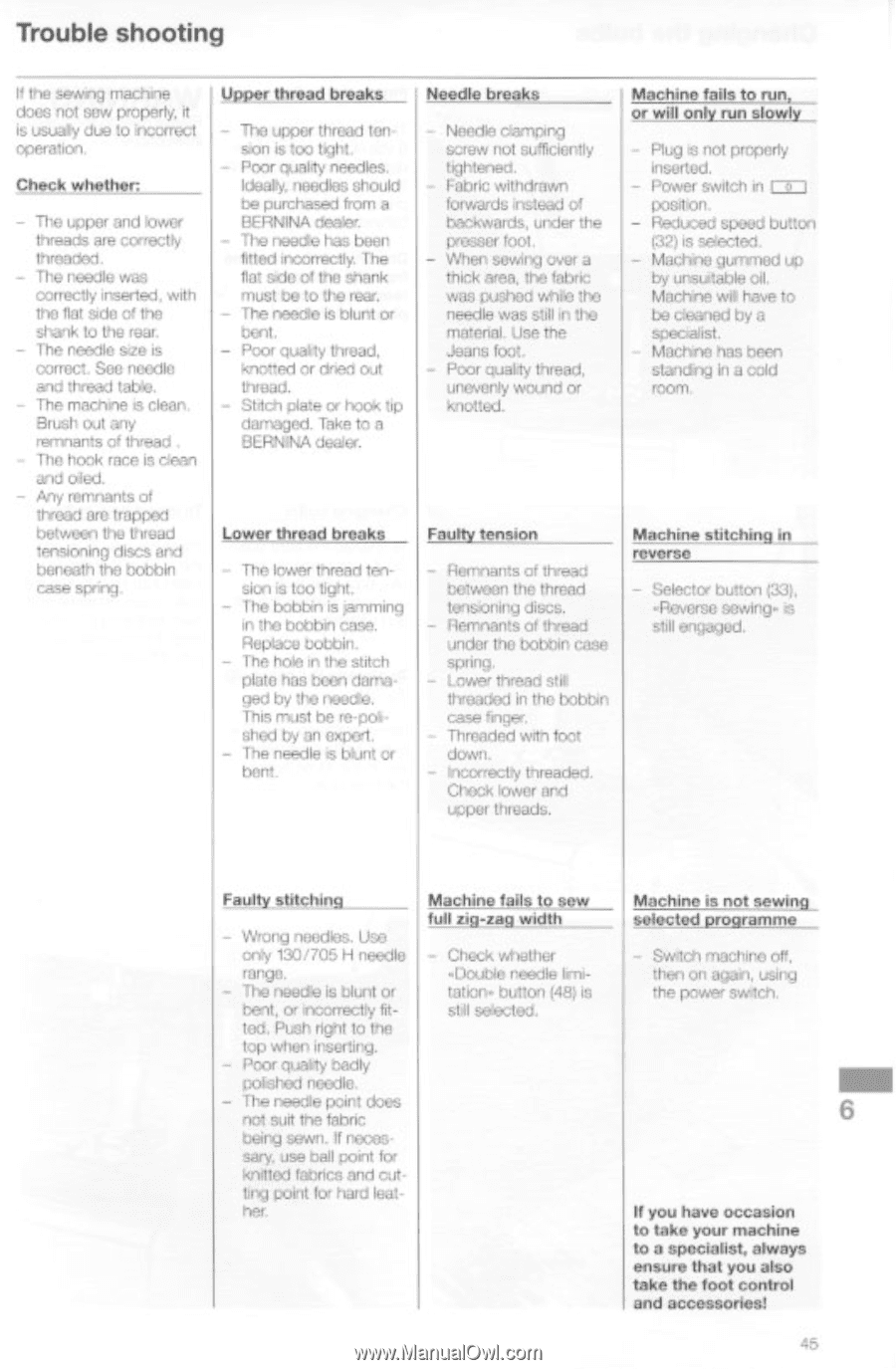

Trouble shooting If the seeing machne does not sow property. it is warty due to mooed °Peahen Check whether: - The WPC( Dad Iowa Elveads are COneolly *weeded. - The needle was Orrectly inserted, with the flat side of the stank to the rear. - The needle sae is correct. See noodle and greed lobe. - The machne 6 clean. Beal oil any remnants of thread The hook race is cean &K} oied. - Any remnants of thread ore trapped betatron the thread tertrgenteg discs and beneath the bobbin case sprig Upper thrsaid breaks - The aver thread ten son is too tight - Prier golly needles. Meaty. needles should be purchased from a BERMNA creek - The needs has been anted ew redly. The not sde ot the shank must be to Ova real. - The reecho is blunt or tent - Poo euaily thread, ignored or drect out thread. - Stitch plate a hook tip damaged. Take to BERNINA claret LOWte thread breaks The loner mein tension rs too Igor - The bobbin is jamming in the bobbin case. Retrace bobbin - The hole in the stitch Olin hos Watt damaged by the reside. This must be re-poi • shed by on expel. - The needle is Want or bent Needle break* Needle damping screw not sufficiently tightened. Fabric withdrawn forwards instead of backwards, under the MOSSO( toe. - When sowing over a thick area. the fabric Was PU211021Ydifie the needle was still in the maternal. Use tae Jeans for. - Poor wally thread, unoveNy wound or knotted. Faulty tension - Harmers of treaa Cowmen the thread tens ring discs. - Remnants al thread under the bobbin ease spring. - Loner thread slit threaded in the bobbin case firma. - Threaded won toot doom ler-amply threaded. Chock lower and Weer threads. Machine fails to run. Or will °MY nn slowly - Plug is nom propedy Insetted. - Power switch in position. - Reduced speed button (32) is seected. - Machne gummed u0 by uneatable 04. Machine Ml have to be cleaned by a specamt. Macke hos been striding in a cold mom Machine stitching in reverts - Selectee button (33), aerate° SewingStill engaged. reittystlielglog - Wrong needles. Use mil 1301705 H needle range. - The needle is blunt or bent, or incorrectly fitted. Rah right lo ink top when i mgrting. - Poor quaity badly mashed rewind. - The recede point does not surf the tater being seem. II Noce.r nary. use ball point for knitted fabrics and cut. ling point la hard leather Machine fails to sow full zig-zag width -Mode needle Imitation- button (48) is slit sierected. Machine is not sewing selected programme - Sween machine or. Men on agar usi kg the power switch If you have occasion to take your machine to a specialist always ensure that you also take the foot control and accessories!