Bernina 43 Manual - Page 27

Problems, Causes

|

View all Bernina 43 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 27 highlights

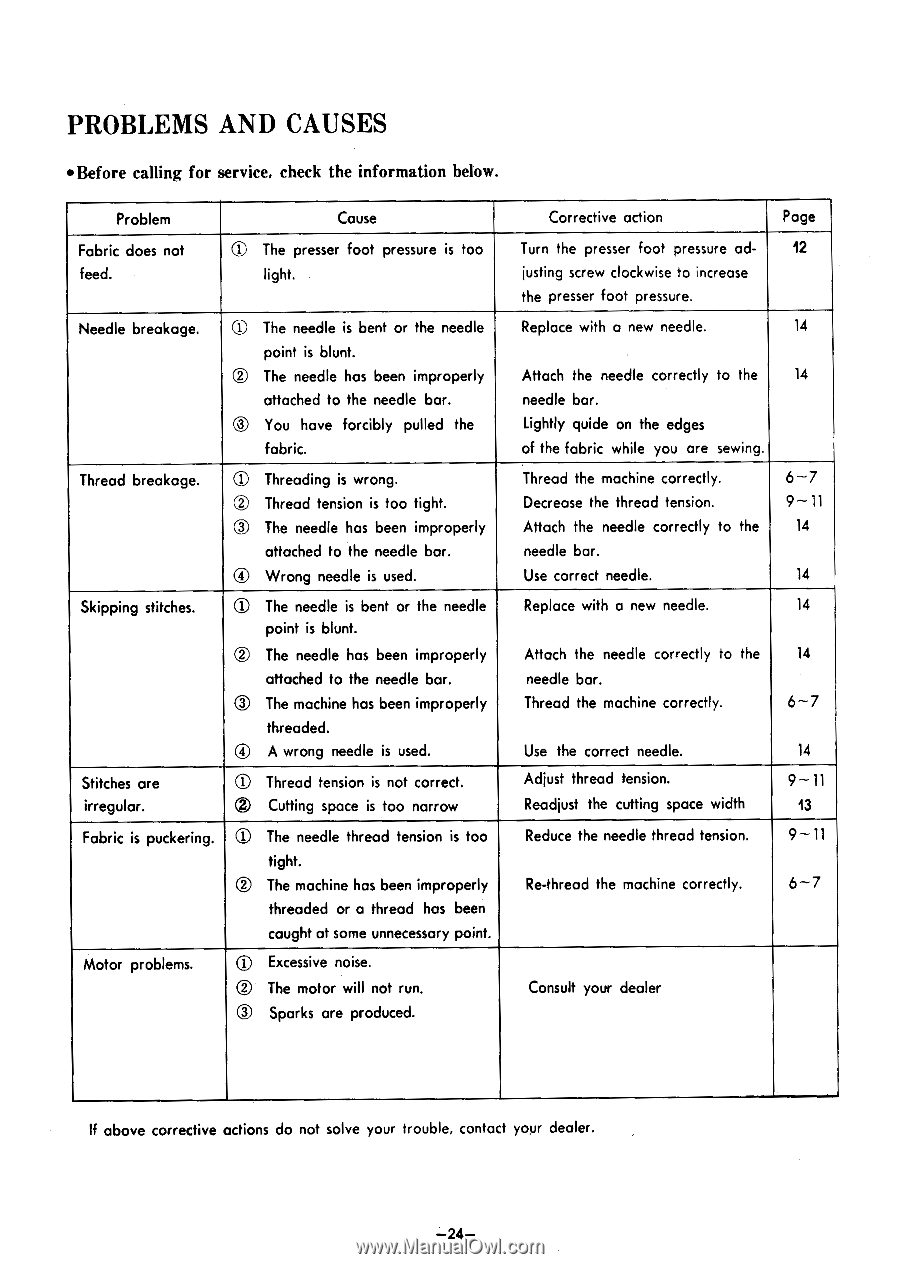

PROBLEMS AND CAUSES •Before calling for service, check the information below. Problem Fabric does not feed. Cause © The presser foot pressure is too light. Needle breakage. C) The needle is bent or the needle point is blunt. ® The needle has been improperly attached to the needle bar. ® You have forcibly pulled the fabric. Thread breakage. Skipping stitches. © Threading is wrong. © Thread tension is too tight. ® The needle has been improperly attached to the needle bar. ® Wrong needle is used. © The needle is bent or the needle point is blunt. © The needle has been improperly attached to the needle bar. ® The machine has been improperly threaded. ® A wrong needle is used. Stitches are irregular. (I) Thread tension is not correct. ® Cutting space is too narrow Fabric is puckering. C) The needle thread tension is too tight. ® The machine has been improperly threaded or a thread has been caught at some unnecessary point. Motor problems. C) Excessive noise. ® The motor will not run. ® Sparks are produced. Corrective action Turn the presser foot pressure adlusting screw clockwise to increase the presser foot pressure. Replace with a new needle. Page 12 14 Attach the needle correctly to the needle bar. Lightly guide on the edges of the fabric while you are sewing. Thread the machine correctly. Decrease the thread tension. Attach the needle correctly to the needle bar. Use correct needle. Replace with a new needle. 14 6 - 7 9-11 14 14 14 Attach the needle correctly to the 14 needle bar. Thread the machine correctly. 6-7 Use the correct needle. Adjust thread tension. Readjust the cutting space width Reduce the needle thread tension. 14 9-11 13 9-11 Re-thread the machine correctly. 6-7 Consult your dealer If above corrective actions do not solve your trouble, contact your dealer. -24-