Brother International BAS-411 Instruction Manual - English - Page 166

Problem, Check, point

|

View all Brother International BAS-411 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 166 highlights

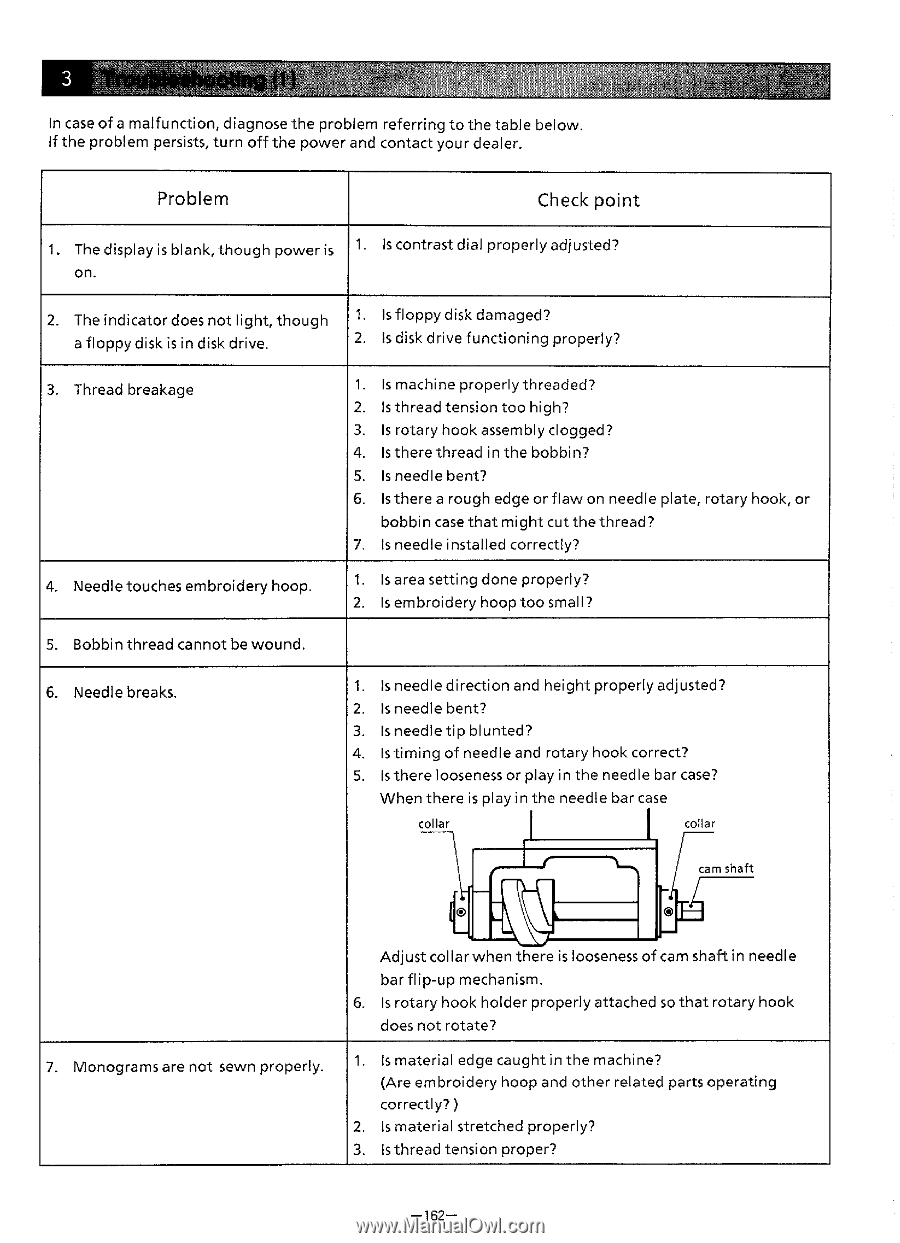

*." 3 ;iS In case of a malfunction, diagnose the problem referring to the table below. If the problem persists, turn off the power and contact your dealer. Problem Check point 1. The display is blank, though power is 1. Is contrast dial properly adjusted? on. 2. The indicator does not light, though 1. Is floppy disk damaged? a floppy disk is in disk drive. 2. Is disk drive functioning properly? 3. Thread breakage 4. Needle touches embroidery hoop. 1. Is machine properly threaded? 2. Is thread tension too high? 3. Is rotary hook assembly clogged? 4. Is there thread in the bobbin? 5. Is needle bent? 6. Is there a rough edge or flaw on needle plate, rotary hook, or bobbin case that might cut the thread? 7. Is needle installed correctly? 1. Is area setting done properly? 2. Is embroidery hoop too small? 5. Bobbin thread cannot be wound. 6. Needle breaks. 1. Is needle direction and height properly adjusted? 2. Is needle bent? 3. Is needle tip blunted? 4. Is timing of needle and rotary hook correct? 5. Is there looseness or play in the needle bar case? When there is play in the needle bar case . collar collar cam shaft 0 7. Monograms are not sewn properly. Adjust collar when there is looseness of cam shaft in needle bar flip-up mechanism. 6. Is rotary hook holder properly attached so that rotary hook does not rotate? 1. Is material edge caught in the machine? (Are embroidery hoop and other related parts operating correctly? ) 2. Is material stretched properly? 3. Is thread tension proper? -162-