Brother International KE-430D Instruction Manual - English - Page 7

Contents, Table Of Error Codes - parts

|

View all Brother International KE-430D manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

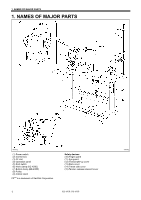

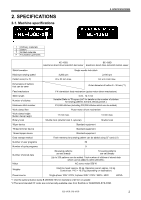

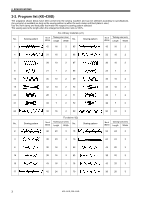

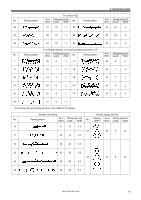

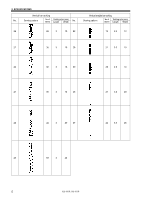

CONTENTS 1. NAMES OF MAJOR PARTS 1 2. SPECIFICATIONS 2 2-1. Machine specifications 2 2-2. Program list (KE-430D 3 2-3. Program list (BE-438D 8 3. INSTALLATION 11 3-1. Table processing diagram 11 3-2. Installing the control box 12 3-3. Installing the oil pan 12 3-4. Installing the machine head 13 3-5. Installing the operation panel 14 3-6. Installing the treadle unit 14 3-7. Installing the cotton stand 15 3-8. Installing the button tray (BE-438D 15 3-9. Installing the eye guard 15 3-10. Connecting the cords 16 3-11. Connecting the ground wire 18 3-12. Installing the back cover 19 3-13. Lubrication 20 3-14. Connecting the power cord 21 3-15. Starting up 22 4. PREPARATION BEFORE SEWING.....23 4-1. Installing the needle 23 4-2. Threading the upper thread 23 4-3. Winding the lower thread 25 4-4. Installing the bobbin case 26 4-5. Thread tension 26 4-5-1. Lower thread tension 26 4-5-2. Upper thread tension 27 4-6. Thread nipper device 28 4-7. Inserting the button (BE-438D 30 4-8. Adjusting the button clamp (BE-438D 30 4-9. Installing the accessory spring (BE-438D) ..... 30 5. USING THE OPERATION PANEL (BASIC OPERATIONS 31 5-1. Name and function of each operation panel item 31 5-2. Setting the program number 33 5-3. Setting the X-scale and Y-scale 33 5-4. Setting the sewing speed 33 5-5. Checking the sewing pattern (KE-430D) ........34 5-6. Checking the sewing pattern (BE-438D) ........35 5-7. Adjusting the work clamp / button clamp lift amount 36 6. USING THE OPERATION PANEL (ADVANCED OEPRATIONS 37 6-1. List of advanced functions 37 6-2. Setting memory switches 38 6-3. List of memory switches 39 6-4. Using the lower thread counter 40 6-5. Using the production counter 41 6-6. Using user programs 42 6-7. Using cycle programs 45 6-8. Direct selection 48 6-9. Loading additional sewing data 48 7. SEWING 49 8. MAINTENANCE 50 8-1. Cleaning the rotary hook 50 8-2. Cleaning the control box air inlet ports ...........51 8-3. Draining the oil 51 8-4. Cleaning the eye guard 51 8-5. Checking the needle 51 8-6. Lubrication 51 8-7. Applying grease (Work clamp: KE-430D 52 8-8. Applying grease (When "GREASEUP" appears 52 9. TABLE OF ERROR CODES 55 KE-430D, BE-438D