Brother International RH-981A Instruction Manual - Spanish - Page 6

Contents, Names Of Each Part, Specifications, Installation, Lubrication, Correct Use, Operation

|

View all Brother International RH-981A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

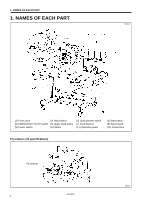

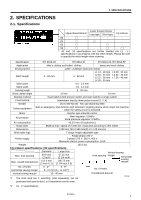

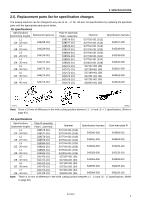

CONTENTS 1. NAMES OF EACH PART 1 2. SPECIFICATIONS 2 2-1. Specifications 2 2-2. Sewing shape 3 2-3. Optional parts 3 2-4. PD-9810, Programmer 3 2-5. Replacement parts list for specification changes 4 3. INSTALLATION 5 3-1. Table processing diagram 5 3-2. Installing the motor 6 3-3. Installing the motor pulley 7 3-4. Installing the control box 7 3-5. Installing the machine head 8 3-6. Installing the oil container 10 3-7. Installing the operation panel 10 3-8. Tightening the V-belt 11 3-9. Installing the spool stand 12 3-10.Installing the hand switch 12 3-11.Installing the air unit and the valve unit .......... 12 3-12. Connecting the wiring 13 3-12-1. Connections inside the control box ......... 14 3-12-2. Connecting the motor cables 15 3-12-3. Connecting the air tubes 15 3-12-4. Securing the cables 16 3-13.Connecting the air tubes 17 3-13-1. Adjusting the air pressure 17 3-14.Connecting the power cord 18 3-15.Installing the programmer (sold separately 19 3-16.Installing the foot switch (option 19 3-17.Installing the indexer (option 20 3-17-1. Installing the indexer main unit 20 3-17-2. Installing the upper thread presser ......... 21 3-17-3. Replacing the plate presser and presser plate 21 3-17-4. Installing the valve unit 21 3-17-5. Connecting the connectors 22 3-17-6. Connecting the air tubes 23 3-17-7. Securing the air tubes and cables 23 3-17-8. Installing the hand switch 24 4. LUBRICATION 25 4-1. Adding oil 25 4-2. Lubrication 25 5. CORRECT USE 27 5-1. Data initialization 27 5-2. Changing the lower thread and gimp trimming 27 5-3. Installing the needle 28 5-4. Threading the upper thread 28 5-5. Threading the lower thread 29 5-6. Threading the gimp 30 5-7. Setting the material 31 5-8. Setting the installation position for cloth feed plate (L) (-52 specifications) ...... 33 5-9. Replacing the PROMs 34 6. OPERATION 35 6-1. Name and function of each operation panel item 35 6-2. Starting up 36 6-3. Program setting method 37 6-3-1. Parameter table ( Taper bar 37 6-3-2. Parameter table ( Straight bar tacking ) ......40 6-4. Cycle program 43 6-5. Production counter 44 6-6. Using the program memos 44 7. SEWING 45 7-1. Automatic sewing 45 7-2. Using the EMERGENCY STOP switch ......... 46 7-3. Adjusting the thread tension 47 7-4. Needle and knife position 48 7-5. Setting the feed bracket to the front position 49 7-6. Switching between single-pedal and dual-pedal operation 49 7-7. Using test feed mode 50 7-8. Using manual mode 51 7-9. Changing the mode during an operation ........ 52 7-10.Moving the cloth feed bar (-52 specifications 52 8. CLEANING AND MAINTENANCE 53 8-1. Cleaning 53 8-2. Draining the oil 54 8-3. Checking the air filter 54 9. STANDARD ADJUSTMENTS 55 9-1. Adjusting the height of the spreader and looper 55 9-2. Adjusting the needle and looper timing........... 56 9-3. Adjusting the loop stroke 57 9-4. Adjusting the height of the needle bar 58 RH-981A